Empowering Engineering Excellence: Innovate, Elevate, Deliver.

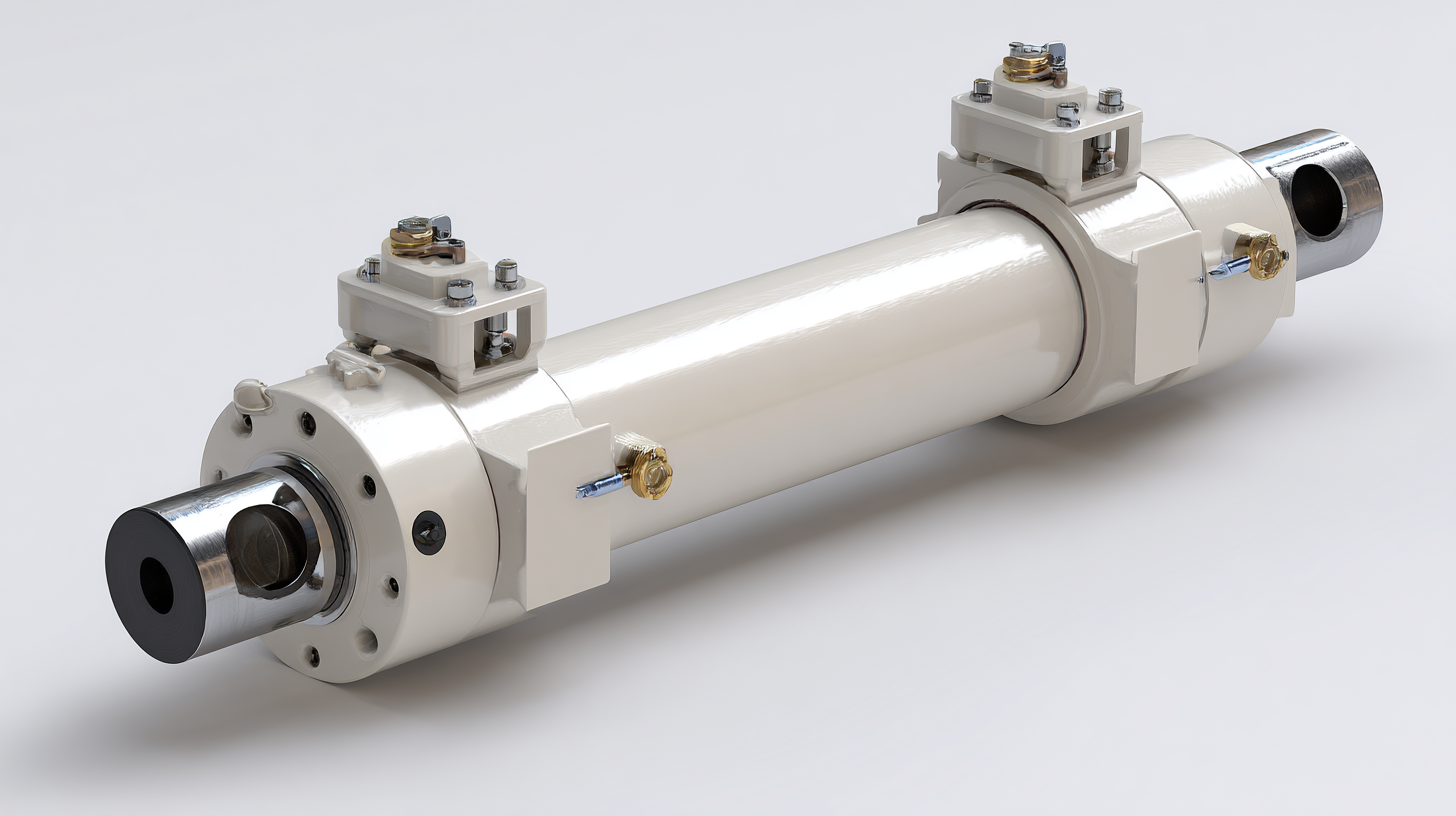

In the ever-evolving landscape of industrial operations, enhancing efficiency and productivity stands as a paramount objective. One of the pivotal contributors to achieving this goal is the utilization of the Double Acting Hydraulic Cylinder. This remarkable device not only provides the capacity to perform work in both directions—extending and retracting—but also offers superior power-to-weight ratios and responsive control. By utilizing hydraulic fluid to create force, Double Acting Hydraulic Cylinders drive various applications such as lifting, pushing, and pulling, making them essential in sectors ranging from manufacturing to construction. As industries increasingly seek to optimize their performance and reduce operational costs, understanding the functionality and advantages of Double Acting Hydraulic Cylinders becomes crucial for engineers and decision-makers alike. This exploration aims to unlock the potential of these hydraulic systems, showcasing how they can significantly enhance industrial efficiency and contribute to the success of modern enterprises.

Double acting hydraulic cylinders play a crucial role in various industrial applications by utilizing hydraulic pressure to extend and retract. This mechanism allows for efficient movement and control in heavy machinery and equipment, maximizing productivity. Unlike single acting cylinders, which can only push in one direction, double acting cylinders provide the capability to generate force in both directions, enabling more complex operations and improving the overall effectiveness of industrial processes.

Understanding the basics of double acting hydraulic cylinders reveals their significance in systems that require precise movements. For instance, in automotive engineering, such as in the sophisticated hydraulic systems of Formula 1 cars, these cylinders are integral for operating multiple sub-systems. The transition from rudimentary, unreliable hydraulic arrangements to advanced systems showcases the evolution and importance of hydraulic technology in enhancing performance and efficiency in various fields. The adaptability and reliability of double acting cylinders make them a foundational component in modern industrial machinery, driving innovation and effectiveness across sectors.

Double acting hydraulic cylinders play a pivotal role in enhancing efficiency across various industrial applications. According to a report by Grand View Research, the global hydraulic cylinder market is projected to reach USD 24.56 billion by 2025, driven largely by the increasing demand for heavy machinery in construction and agriculture. In these sectors, double acting cylinders are preferred for their ability to generate force in both the extend and retract phases, resulting in a more efficient operation that maximizes productivity.

In manufacturing, double acting cylinders are essential in automation systems, particularly in material handling applications. A study from MarketsandMarkets indicates that the industrial automation market is expected to grow from USD 175 billion in 2021 to USD 295 billion by 2026. In this context, double acting cylinders facilitate precise control and faster cycle times, outperforming single acting systems. This improvement is crucial for assembly lines where time efficiency directly correlates with output rates and profitability. As industries continue to evolve, the integration of double acting hydraulic cylinders is set to further revolutionize operational capabilities, ensuring enhanced productivity and reliability in various applications.

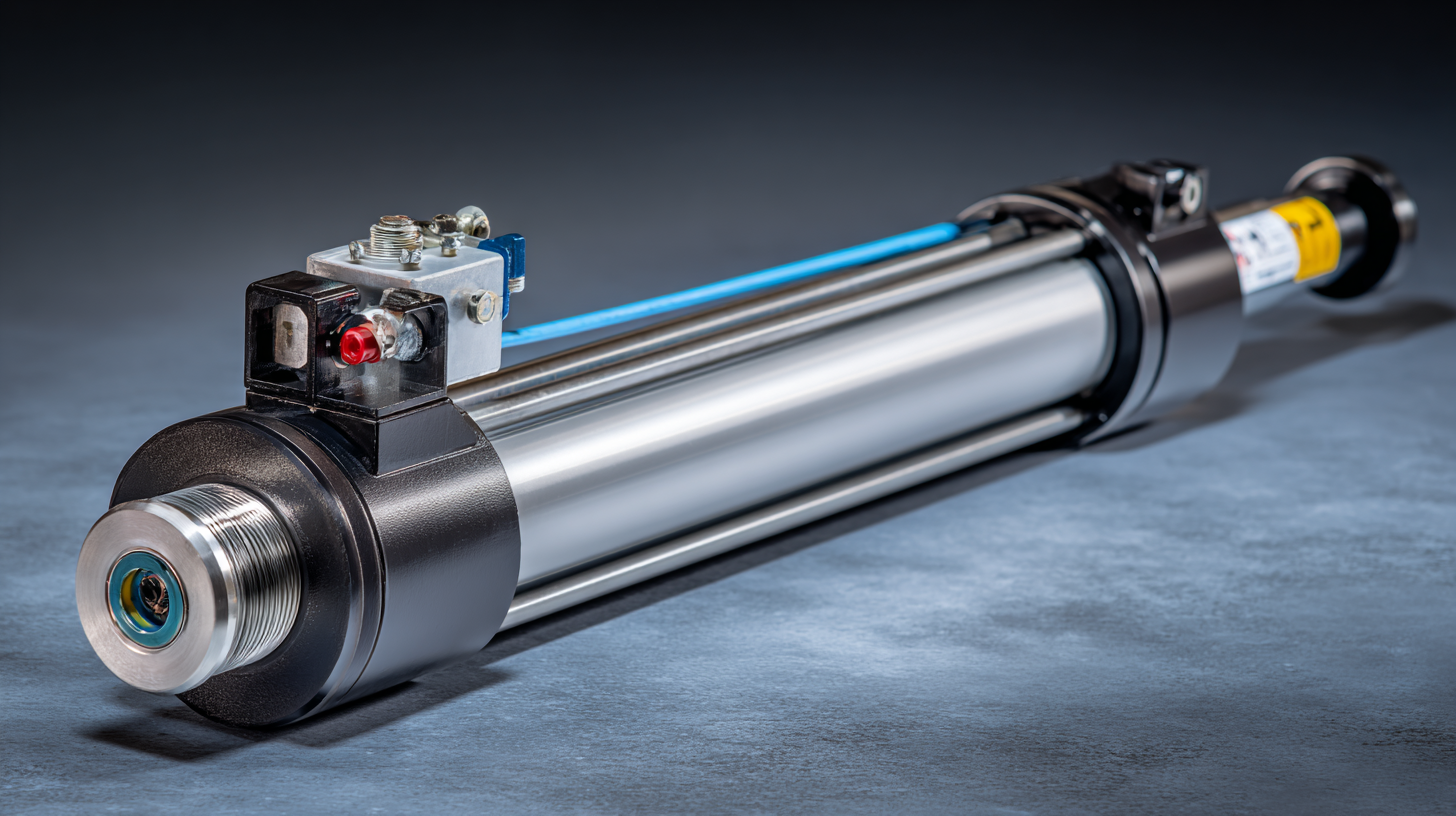

Double acting hydraulic cylinders have become essential in enhancing operational efficiency across various industrial applications. Their design allows for power in both extensions and retractions, maximizing productivity, particularly in environments like terminals and construction sites where conditions can be challenging. A recent report highlights that the demand for reliable motion control solutions is on the rise, driven by industries aiming to boost productivity and lower operational costs (OPEX). The push towards more energy-efficient hydraulic systems is also indicative of the industry's commitment to sustainability while enhancing performance.

Tips for maximizing the benefits of double acting hydraulic cylinders include regular maintenance checks to ensure optimal performance and investing in automation technologies. For instance, integrating automated guided vehicles (AGVs) in hydraulic operations can significantly reduce downtime and enhance throughput by eliminating manual handling and optimizing workflow. Furthermore, employing advanced control strategies, such as deep reinforcement learning in hydraulic servo systems, can lead to greater precision and responsiveness in operations, further driving efficiency.

In addition, proper selection and sizing of hydraulic cylinders based on specific application needs can greatly impact overall system performance. According to industry analysis, the hydraulic equipment market is set to experience growth, with innovations aimed at increasing productivity through enhanced design and operational capabilities. Leveraging these advancements will undoubtedly allow businesses to achieve greater profitability and operational efficiency in their processes.

| Dimension | Value | Impact on Efficiency |

|---|---|---|

| Stroke Length | 200 mm | Allows for greater range of motion |

| Max Pressure | 350 bar | Increases lifting capability |

| Cycle Time | 12 seconds | Enhances productivity |

| Operating Temperature | -20 to 80 °C | Ensures reliability in various environments |

| Volume of Oil | 5 L | Reduces energy consumption |

| Return Time | 8 seconds | Quicker response enhances workflow |

Maintaining double acting hydraulic cylinders is essential for ensuring optimal performance and longevity in industrial applications. Regular inspection and servicing can prevent premature wear and potential breakdowns, ultimately enhancing overall productivity. One key practice is to keep the cylinders clean and free from contaminants. Dirt and debris can cause significant damage to seals and internal components, leading to leaks and reduced efficiency.

Tips: Always use a soft cloth to clean the exterior of the cylinder and ensure the rod is wiped down before retracting it to prevent contaminants from entering the system. Additionally, monitor the hydraulic fluid levels and quality. Low fluid levels or the presence of water or other impurities can compromise the system's operation. Routine fluid checks and changes can help maintain the efficiency of the hydraulic system.

Regularly lubricating moving parts is another best practice. This reduces friction and wear, making the system more responsive and efficient. Operators should adhere to the manufacturer’s specifications regarding lubricant types and schedules to ensure optimal performance. Consider scheduling maintenance during off-peak hours to minimize downtime while keeping the machinery in peak condition.

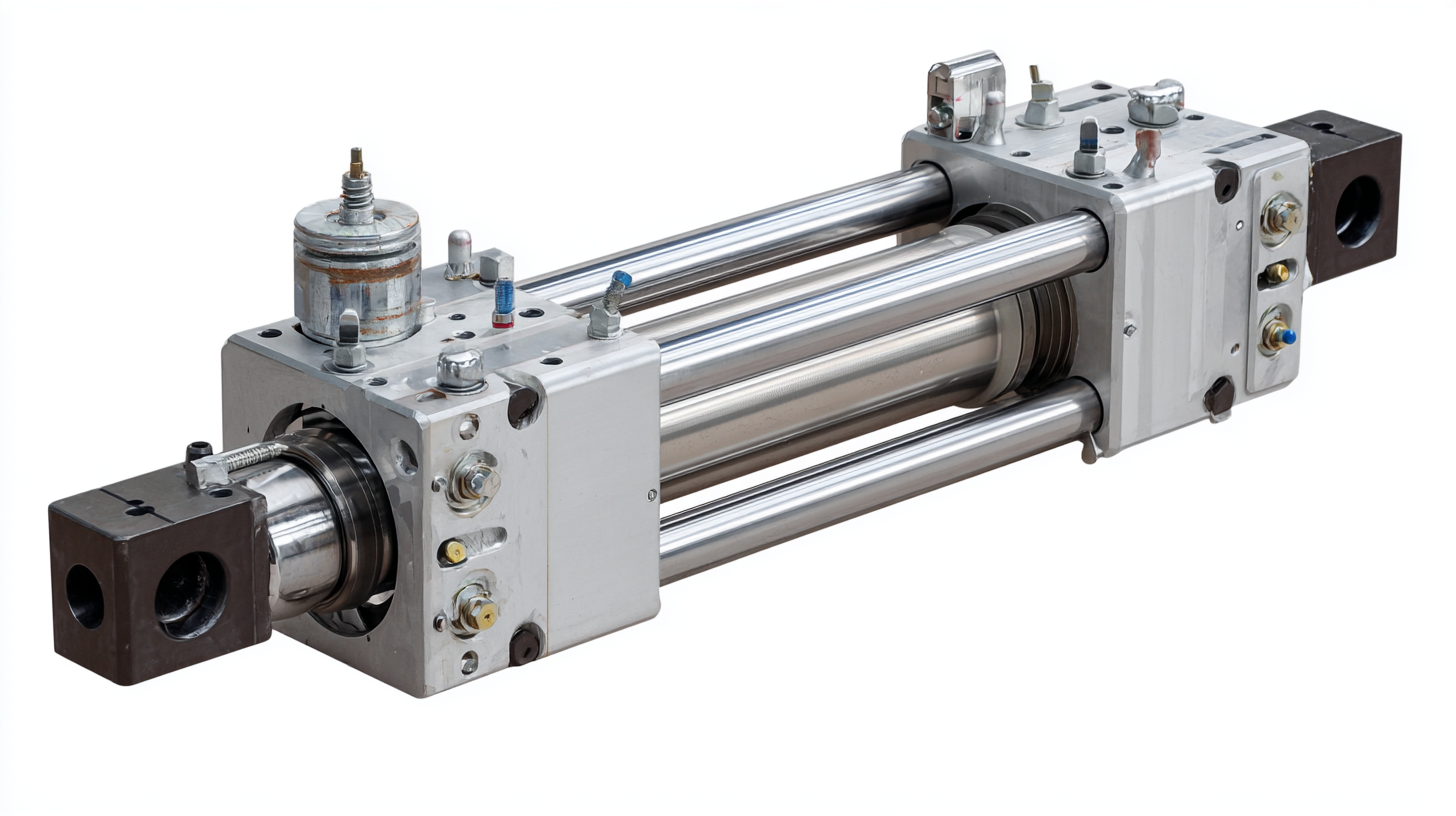

Integrating double acting hydraulic cylinders into existing systems can significantly enhance operational performance across various industries. These cylinders, which utilize hydraulic fluid to move in both directions, provide consistent force in retraction and extension, making them ideal for tasks requiring precision and power. By retrofitting current machinery with these cylinders, businesses can achieve smoother operations, reduce wear and tear, and minimize downtime due to mechanical failures.

To effectively implement double acting hydraulic cylinders, it’s essential to evaluate the compatibility of existing systems. This may involve assessing hydraulic fluid compatibility, pressure ratings, and physical space constraints. Additionally, proper training for operators and maintenance personnel is critical to ensure optimal performance and safety. With strategic integration, companies can not only improve efficiency but also enhance the overall reliability of their machinery, leading to increased productivity and cost savings over time.