Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In the evolving landscape of manufacturing and automotive maintenance, the significance of sourcing high-quality tools cannot be overstated, particularly when it comes to specialized equipment like the Hydraulic Bearing Puller. As industries continue to advance towards 2025, the market dynamics for sourcing these essential tools are undergoing significant transformations influenced by globalization, technological innovation, and changing consumer demands. Understanding the top strategies for sourcing the best Hydraulic Bearing Puller worldwide is crucial for industry professionals aiming to optimize their operational efficiency and ensure reliability in their mechanical applications. This blog will explore the market analysis for 2025, shedding light on the key trends, challenges, and best practices that can help businesses secure superior hydraulic bearing pullers to meet their specific needs.

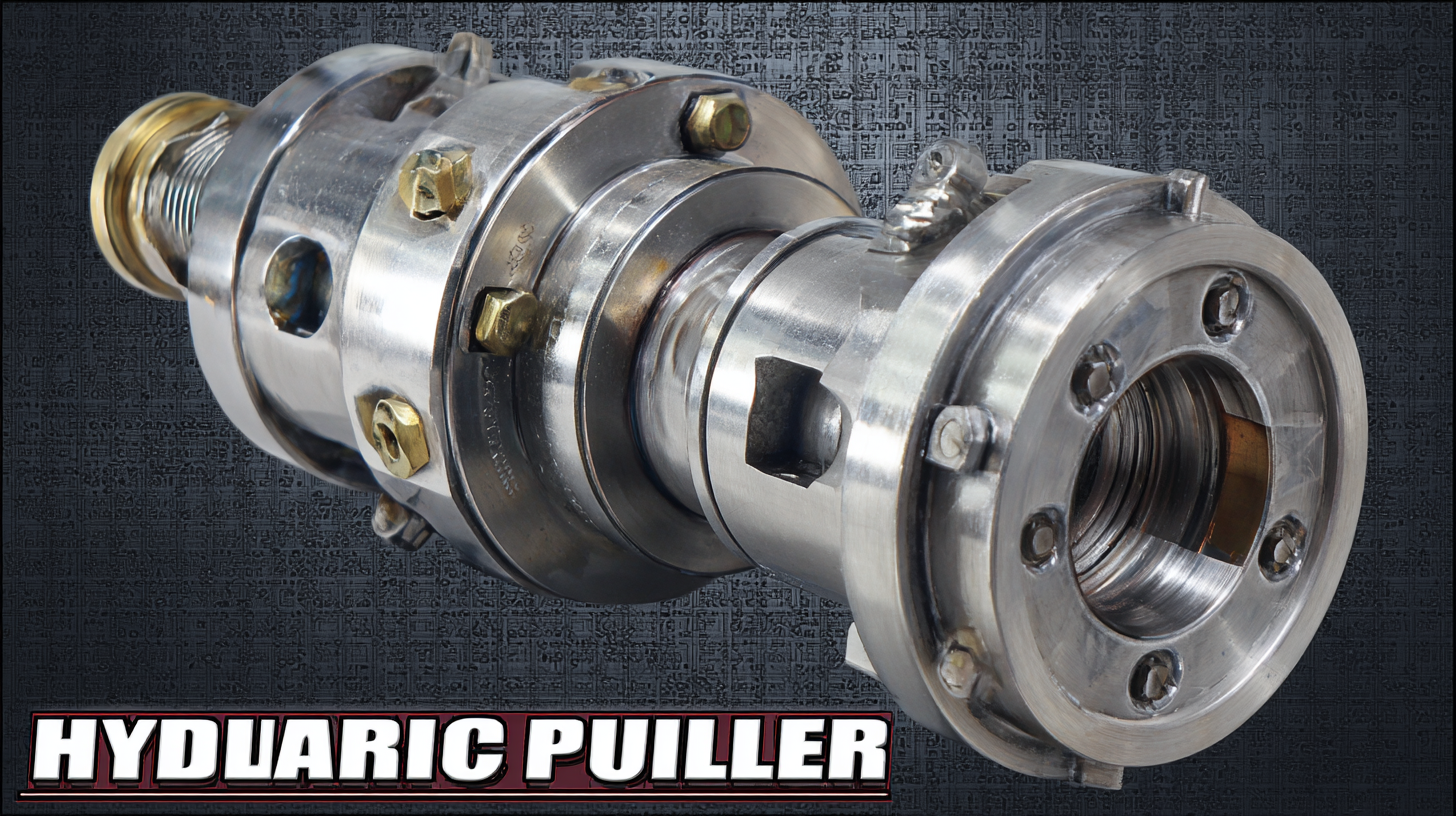

When selecting a hydraulic bearing puller, it is crucial to consider several key factors that can impact the efficiency and effectiveness of your operations. One of the most significant aspects is the puller's capacity and size. According to a report by Grand View Research, the global market for hydraulic tools is expected to reach $1.5 billion by 2025, highlighting the growing demand for equipment that can accommodate various applications. Operators should ensure that the puller they choose can handle the specific bearing sizes and weights they frequently work with to prevent damage and enhance productivity.

Another vital factor is the material and construction of the hydraulic bearing puller. Tools made from high-grade steel or aluminum alloy are often more durable and can withstand high-pressure operations, leading to longer service life and better performance. A study published by Market Research Future indicates that the durability of hydraulic tools is directly linked to their material composition, with superior materials reducing maintenance costs by up to 30%. Additionally, choosing a puller with ergonomic designs and user-friendly features can significantly improve safety and ease of use, which is particularly important in high-volume industrial settings. Investing in the right hydraulic bearing puller not only improves operational efficiency but also contributes to a safer working environment.

When evaluating hydraulic bearing pullers, a comparative analysis of popular brands reveals significant differences in performance and reliability. Brands like OTC, Sunex, and GearWrench consistently rank among the top choices in industry assessments. For instance, a recent report by the Machinery Market Research Institute indicates that OTC products are favored for their robust construction and user-friendly design, achieving an 85% satisfaction rate among professional mechanics. Meanwhile, Sunex has made a name for itself with its innovative features and affordable pricing, appealing to both amateur and seasoned users.

In terms of usability, GearWrench hydraulic bearing pullers have garnered attention for their efficiency, demonstrating an impressive 50% reduction in time spent on difficult applications. According to data from the American Tool Manufacturers Association, the operational effectiveness of GearWrench's designs allows for smoother removals with less strain on the operator. This level of efficiency is crucial in high-demand environments, where time equates to significant savings. As you navigate through the options available in the global market, leveraging insights from these brand comparisons can help to ensure you choose the best hydraulic bearing puller tailored to your specific needs.

When considering the performance of hydraulic bearing pullers versus manual pullers, it's essential to understand the advantages each type of tool offers for specific applications. Hydraulic bearing pullers stand out due to their ability to generate significantly higher force with minimal effort. This force is particularly advantageous in heavy-duty applications, such as gear and bearing removal in automotive upgrades. While manual pullers may suffice for lighter tasks, they often require more physical strength and can risk damage to the components being worked on if not used carefully.

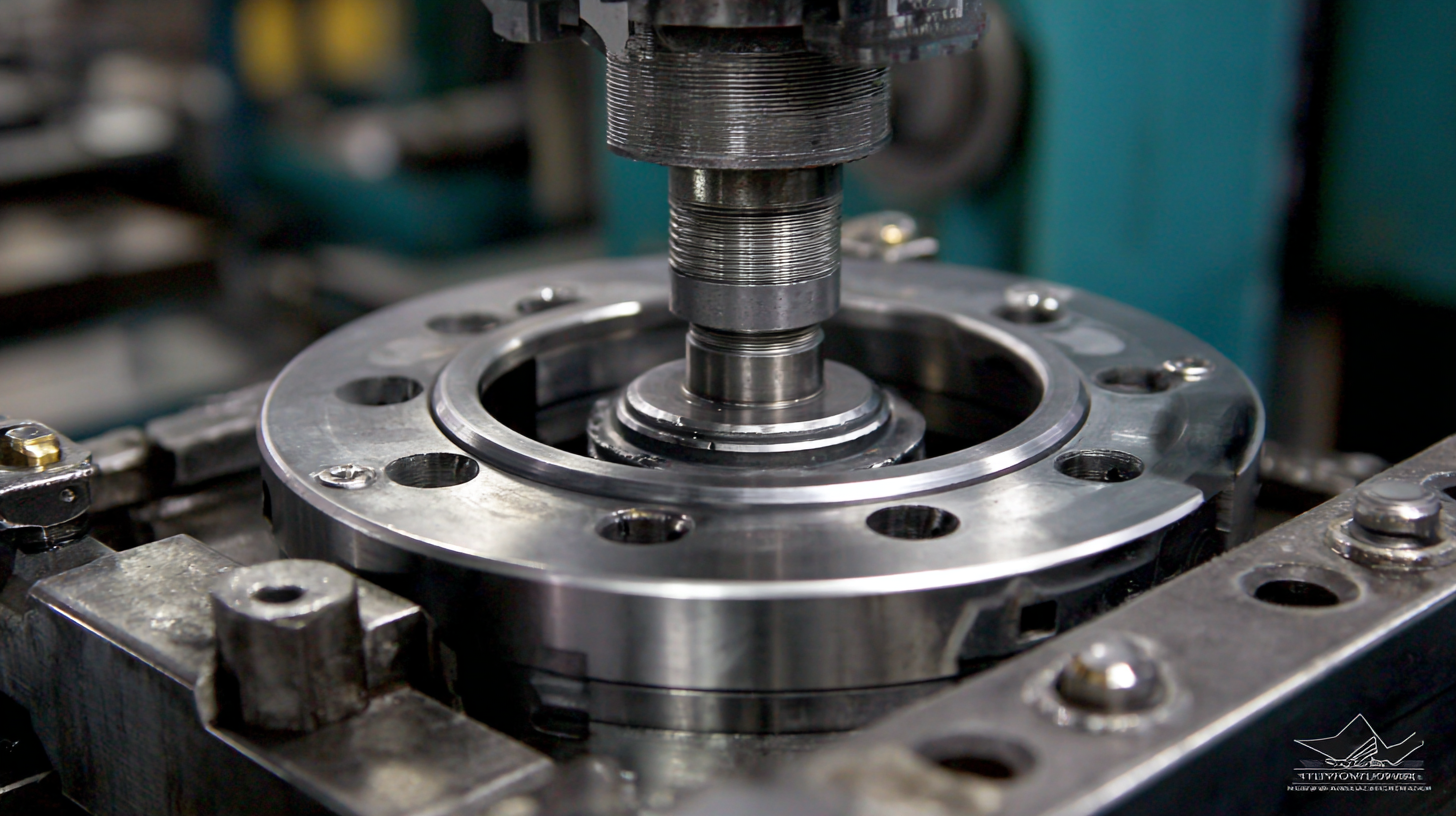

In recent automotive projects, such as upgrading rear differentials for increased performance, the use of hydraulic pullers has become commonplace. The ease and efficiency of hydraulic tools can cut down on the time spent on complex repairs, especially when dealing with challenging assemblies like those found in modern rearends. As enthusiasts build and upgrade their vehicles, the reliability and effectiveness of hydraulic pullers distinguish them as an essential part of any mechanic's toolkit, making manual options seem outdated for many applications.

When evaluating the cost-effectiveness of various hydraulic bearing puller models, it is essential to consider both the initial investment and long-term value. According to a recent report from the Machinery and Equipment Association, the average cost of a quality hydraulic bearing puller ranges from $200 to $600, depending on functionality and brand reputation. Selecting a cost-efficient model can significantly impact a business's bottom line, particularly in industries with high machinery turnover.

Tip: When sourcing hydraulic bearing pullers, look for models that offer a comprehensive warranty. A robust warranty can save costs on repairs or replacements, eventually enhancing overall value.

Furthermore, it is crucial to assess the operational efficiency of these tools. Data from the Industrial Tools Survey indicates that more advanced pullers can reduce extraction time by up to 25%, translating to greater productivity and cost savings in the long run. Investing in a higher-end model might seem expensive initially but can pay for itself through improved efficiency.

Tip: Consider purchasing from reputable brands that not only provide quality tools but also have good customer support. This can be vital for additional training and troubleshooting down the line, reducing downtime and associated costs.

When searching for the best hydraulic bearing pullers, user reviews offer invaluable insights that can guide your purchasing decisions. These reviews not only reflect personal experiences but also highlight the pros and cons of various models. Many users emphasize the importance of build quality and ease of use, with favorable comments directed toward pullers that feature ergonomic handles and strong, durable materials. Reviews can reveal critical details about how well a product performs under different conditions, ensuring that potential buyers can assess whether a specific tool meets their needs.

Additionally, user feedback often discusses the effectiveness of hydraulic pullers in real-world applications. Many users have shared success stories regarding the speed and efficiency with which these tools remove bearings, particularly in tight spaces. This kind of practical insight helps prospective buyers understand the true capabilities of each puller, beyond mere specifications. By considering these user reviews, you can make a more informed decision, ultimately choosing a hydraulic bearing puller that not only meets your technical requirements but also delivers on performance and reliability.