Empowering Engineering Excellence: Innovate, Elevate, Deliver.

The field of orthopedic implants is rapidly evolving. According to a report by the Orthopedic Research Society, the global orthopedic implant market is expected to reach $66 billion by 2025. This significant growth is driven by technological advancements and increasing demand for joint replacements. Innovations in materials, design, and surgical techniques are changing the landscape.

Recent studies indicate that about 15 million orthopedic procedures occur annually in the United States alone. These include knee and hip replacements, which are among the most common surgeries. Despite these advancements, challenges remain. Issues like implant longevity and patient recovery time require continuous attention. Not all innovations are successful; some fail to meet expectations.

Emerging orthopedic implant technologies promise better outcomes and reduced complications. 3D printing, for instance, enables personalized implants tailored to individual patient anatomy. Such innovations can lead to faster recovery and improved functionality. However, the adoption of new technologies often presents hurdles. Health professionals need training, and regulatory approval can delay implementation. Balancing innovation with practicality is essential in this ever-changing field.

The field of orthopedic implants is evolving rapidly. Innovations in biodegradable materials are particularly exciting. These implants can dissolve in the body, eliminating the need for a second surgery. Reports indicate that around 30% of patients experience complications from traditional implants. This factor has driven research into alternative solutions.

3D printing technology is reshaping the orthopedic field. This innovation allows for the production of customized implants tailored to each patient's anatomy. The result is improved fitting and potentially faster recovery. These implants can reduce the risk of complications, yet they are not without challenges.

One of the critical aspects is material selection. Not all materials perform well in a biological environment. Researchers are constantly experimenting with biocompatible substances. However, results can be inconsistent. Some 3D-printed implants may not integrate well with human tissue, leading to complications. This aspect requires further study and refinement.

Another point of consideration is the cost. While 3D printing can lower production expenses over time, initial setup costs can be high. Not every healthcare facility can afford this technology. Access remains uneven across regions, creating disparities in patient care. Efforts must be made to address these issues to fully realize the potential of 3D printing in orthopedics.

Smart implants are revolutionizing orthopedic care. With embedded sensor technology, these devices provide real-time data on patient recovery and implant performance. A recent report by Markets and Markets stated that the orthopedic sensor market is projected to reach USD 3 billion by 2027. This growth highlights the increasing demand for smarter solutions in healthcare.

The integration of sensors allows for continuous monitoring of factors such as temperature and movement. This data can lead to quicker interventions when complications arise. Yet, challenges remain. Privacy concerns loom over the collection and sharing of personal health data. Furthermore, not all sensors are reliable, leading to potential misinterpretations.

Additionally, the cost of implementing these technologies can be significant. Hospitals may struggle with funding these advanced solutions. There is also a variable learning curve for staff. Training is essential for effectively utilizing these smart devices. The promise of enhanced patient care is tantalizing, yet the execution must be meticulously addressed.

| Innovation | Description | Benefits | Key Features |

|---|---|---|---|

| Smart Implants | Implants equipped with sensors for real-time monitoring | Enhanced patient outcomes through data-informed decisions | Integrated sensors, wireless communication, data analytics |

| Customized 3D Printed Implants | Implants designed to fit the individual patient's anatomy | Improved fit and reduced recovery time | Patient-specific design, rapid production, biomaterials |

| Resorbable Implants | Implants that dissolve after fulfilling their function | Elimination of secondary surgeries for removal | Biodegradable materials, gradual strength reduction |

| Smart Knee Sensors | Knee implants with sensors to track movement metrics | Personalized rehabilitation plans | Motion tracking, data analysis for improvements |

| Nano-coating Technology | Surface treatment that reduces infection risk | Lowered infection rates and improved patient outcomes | Hydrophobic surfaces, antibacterial properties |

| Active Fixation Devices | Devices that adjust to changes in bone structure | Increased stability and longevity of implants | Dynamic adjustment mechanisms, adaptive materials |

| Sensor-embedded Rods for Spine | Spinal rods with embedded sensors for monitoring | Real-time data on spinal alignment and loads | Continuous monitoring, data collection for predictions |

| Graphene-Enhanced Implants | Implants made with graphene for improved strength | Higher durability with reduced weight | Lightweight structure, enhanced mechanical properties |

| Virtual Reality in Surgical Planning | Use of VR technologies for pre-surgical simulations | Improved surgical outcomes and planning accuracy | 3D models, enhanced visualization for surgeons |

| Augmented Reality for Training | AR tools to train surgeons in implant procedures | Improved training experiences for better skills | Interactive simulations, real-time feedback |

In recent years, orthopedic implants have undergone significant advancements. Enhanced joint replacement solutions focus on innovative materials and design. These improvements aim to increase longevity and functionality for patients. For instance, a recent study by the American Academy of Orthopaedic Surgeons indicates that new materials like titanium alloys and polyethylene composites boost implant durability by up to 50%.

Design innovations also play a critical role. Researchers are exploring 3D printing technologies to create patient-specific implants. This customization can lead to better fit and performance, potentially reducing recovery time. However, despite these advancements, challenges remain. Many implants still face issues like infection rates or mechanical failure. Data shows that 5-10% of joint replacements require revision within 10 years, a figure that underlines the need for continuous improvement.

The focus on enhanced solutions is evident, yet the industry must address these issues critically. Balancing cutting-edge design with practical longevity is vital. As the field evolves, the dialogue around these advancements must include ongoing patient outcomes. Only through reflection and innovation can true progress be made in orthopedic implant technology.

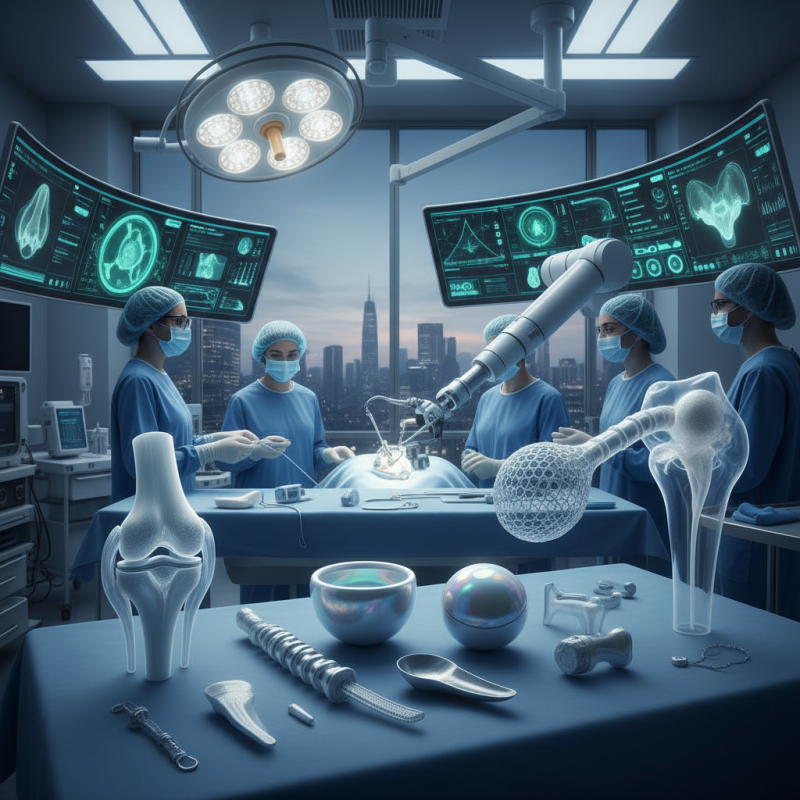

Robotics and AI are reshaping orthopedic surgery. These technologies enhance precision in implant procedures. Surgeons can now utilize advanced robotic systems. This allows for more accurate placements of implants, reducing complications. The data gathered during surgeries also contributes to improving techniques. Each operation helps refine algorithms and methods.

However, reliance on technology raises concerns. Human oversight is essential, as machines can falter. Technical glitches or software errors may lead to issues during surgery. Balancing AI capabilities with human expertise is critical. While robots can aid, the surgeon's judgment remains invaluable.

Moreover, patient outcomes are not guaranteed. Some patients may still experience discomfort or complications. Continuous evaluation of robotic systems is necessary. Innovation must not outpace regulations or ethical considerations. The integration of robotics and AI poses both challenges and opportunities. The field is evolving, and it requires careful navigation to ensure better patient care.