Empowering Engineering Excellence: Innovate, Elevate, Deliver.

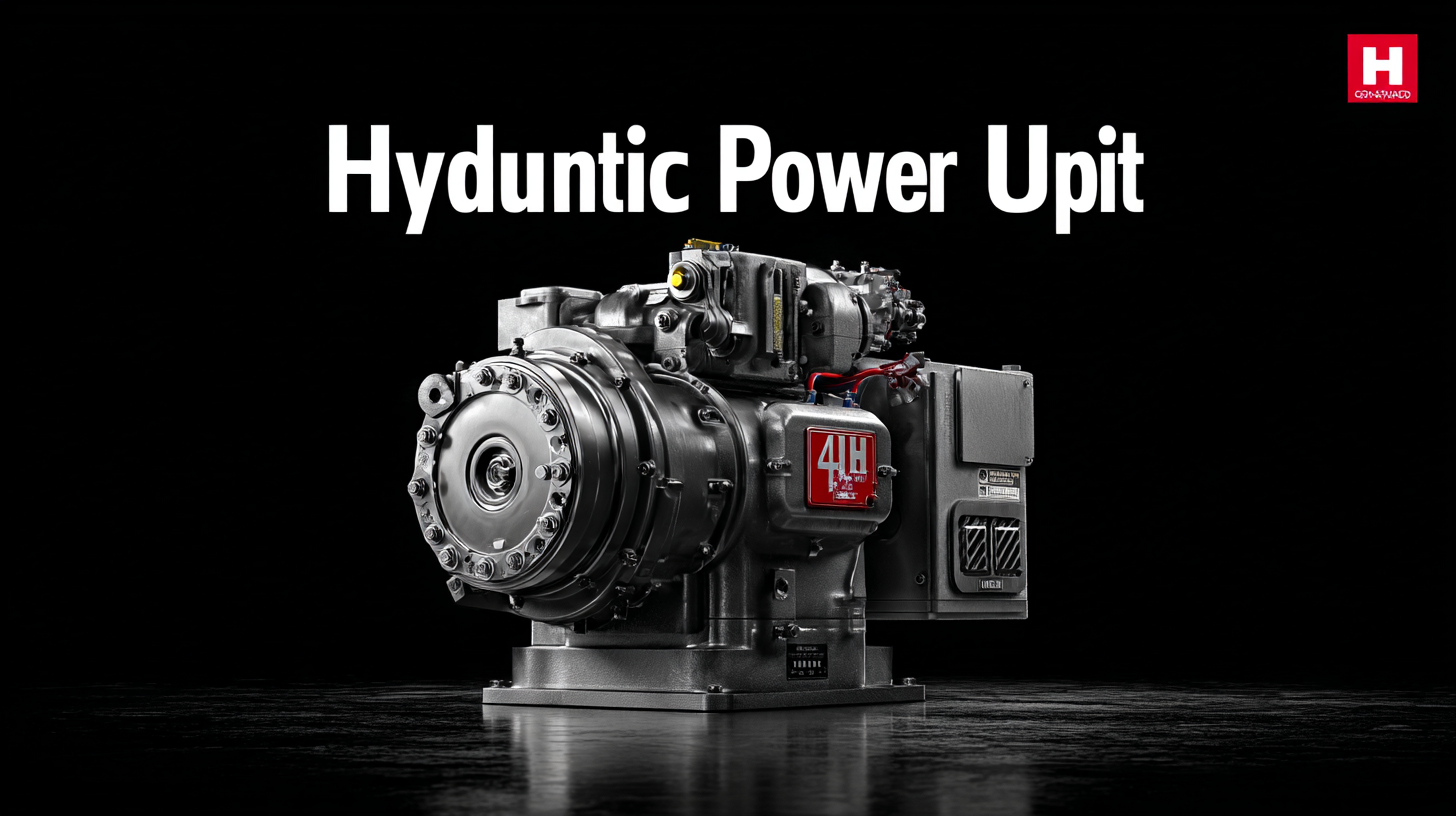

In the realm of industrial machinery, the Hydraulic Power Unit (HPU) serves as a vital component, providing the necessary power to drive various hydraulic systems effectively. With a diverse array of designs and features available, selecting the right HPU can significantly influence the efficiency and productivity of operations across multiple sectors. This blog aims to unveil the top hydraulic power units on the market by conducting a comprehensive industry comparison. By examining key performance metrics, technological advancements, and user feedback, we will highlight examples of exceptional hydraulic power units that stand out in terms of reliability, efficiency, and durability. Whether you're an industry veteran or a newcomer looking to optimize your hydraulic systems, this guide will provide valuable insights to aid your decision-making process.

Hydraulic power units (HPUs) play a crucial role in various industries, providing the essential hydraulic energy required for a multitude of applications. When comparing popular types of hydraulic power units, it’s vital to assess their performance metrics such as pressure output, flow rate, and energy efficiency. Gear-driven HPUs, for instance, are known for their compact design and ability to deliver high-pressure outputs, making them suitable for applications like construction machinery and material handling. Conversely, piston-driven HPUs offer better efficiency and higher power density, which is ideal for industrial automation and manufacturing settings.

In addition to performance metrics, the applications of different HPUs can significantly affect the choice of unit. For example, electric-driven hydraulic power units provide a cleaner alternative for environments that require reduced emissions, while diesel-powered options deliver robust power for remote and heavy-duty applications. By understanding the unique strengths and limitations of each type, industry professionals can select the most suitable hydraulic power unit that aligns with their operational needs and performance expectations.

| Hydraulic Power Unit Type | Max Pressure (psi) | Flow Rate (GPM) | Motor Power (HP) | Typical Applications |

|---|---|---|---|---|

| Fixed Displacement | 3000 | 10 | 5 | Construction Equipment |

| Variable Displacement | 4000 | 15 | 10 | Industrial Automation |

| Compact | 2500 | 8 | 3 | Agricultural Machinery |

| Portable | 2000 | 5 | 1.5 | Maintenance and Repair |

| Stationary | 3500 | 12 | 7.5 | Manufacturing Systems |

Hydraulic power units (HPUs) are crucial components in various industrial applications, providing the necessary force and control for machinery to operate effectively. Understanding the key technical specifications—capacity, pressure, and efficiency—allows users to select the most appropriate unit for their specific needs. Capacity refers to the volume of hydraulic fluid that the unit can hold and deliver, which directly impacts the performance of hydraulic systems. An HPU with a higher capacity can run larger systems or multiple machines simultaneously, making it essential for heavy-duty applications.

Pressure is another critical specification, as it determines the force that the hydraulic system can exert. Typical pressure ratings may vary, but units capable of operating at higher pressures are often preferred for demanding tasks. Greater pressure enhances the efficiency of hydraulic acts, enabling quicker operation and more precise control.

Moreover, efficiency is vital in assessing the overall performance of an HPU, as it affects energy consumption and operational costs. Higher efficiency ensures that less energy is wasted during the hydraulic process, contributing to both economic savings and reduced environmental impact. By evaluating these specifications, industry professionals can make informed decisions and optimize their hydraulic operations.

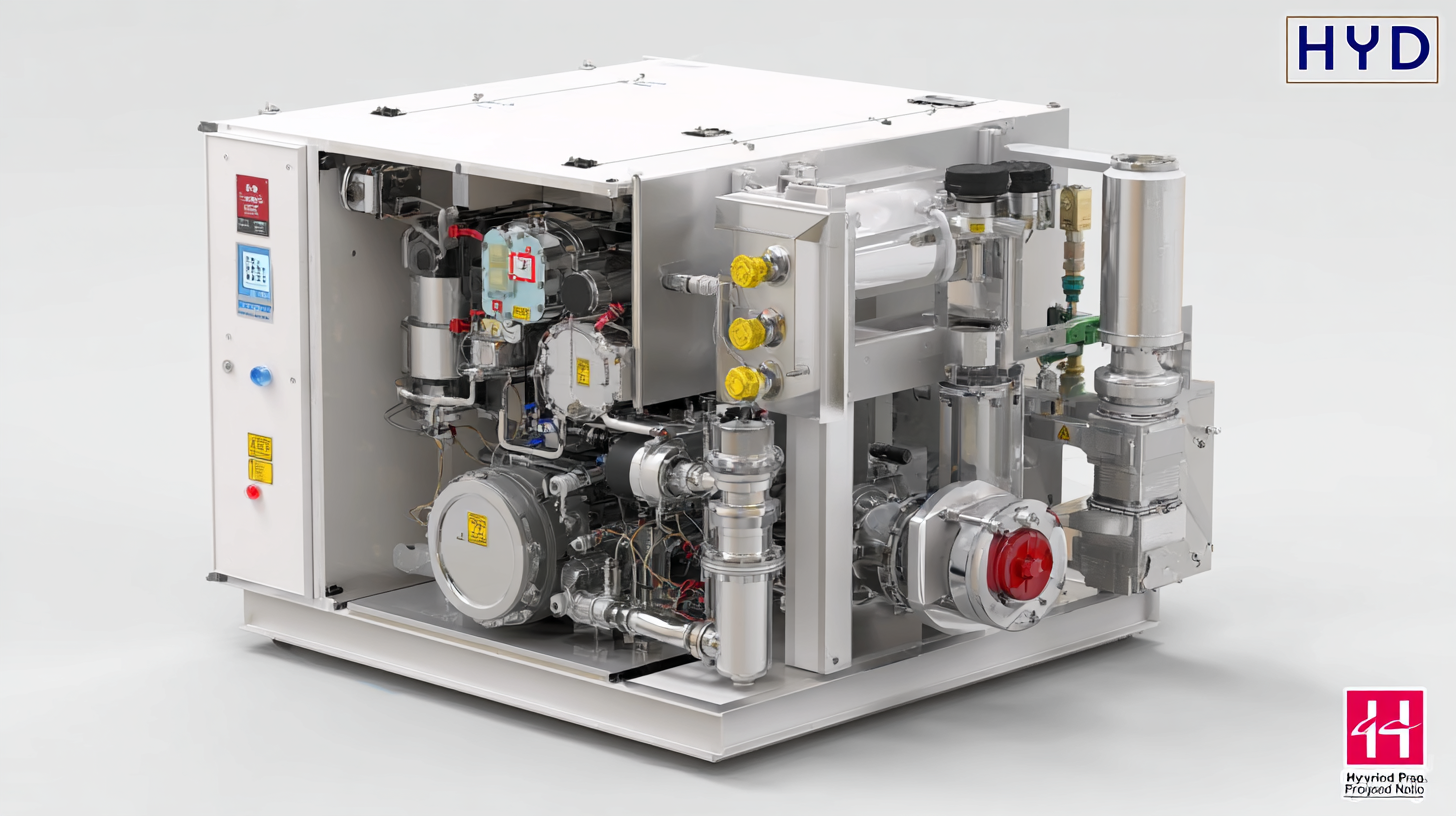

The hydraulic power unit (HPU) market is witnessing a transformative shift with the emergence of electric and hybrid alternatives. According to a report by MarketsandMarkets, the global electric hydraulic power unit market is projected to grow from USD 1.67 billion in 2020 to USD 2.67 billion by 2026, reflecting a robust CAGR of 9.5%. This growth is driven by the increasing demand for energy-efficient solutions amid rising environmental concerns. Electric HPUs are gaining traction due to their reduced noise levels and lower emissions compared to traditional hydraulic systems.

In addition to electric units, hybrid hydraulic power systems are also capturing attention in the industry. A recent analysis by Research and Markets highlighted that hybrid hydraulic systems, which combine the benefits of both electric and hydraulic technologies, are poised to disrupt conventional practices in various sectors, including construction and manufacturing. The flexibility and efficiency of hybrid systems present a compelling case for industries aiming to optimize operational costs while minimizing environmental impact. As electric and hybrid options continue to develop, they are expected to play a crucial role in the future landscape of hydraulic power units, appealing to sectors committed to sustainability and innovation.

When evaluating hydraulic power solutions, cost analysis plays a crucial role in determining their economic viability. According to a recent report from the Hydraulic Institute, the initial purchase cost of hydraulic power units (HPUs) can vary significantly, ranging from $2,000 to over $50,000 depending on the complexity and specifications of the units. Factors such as system capacity, efficiency ratings, and integration needs contribute to this price disparity, prompting businesses to conduct a thorough analysis of long-term operational costs in relation to upfront fees.

Moreover, operational efficiency is a key driver of overall costs. Data from the American Society of Mechanical Engineers indicate that HPUs with variable speed drives can reduce energy consumption by up to 30%, translating to significant savings over time. For companies that rely heavily on hydraulic systems, this reduction can represent thousands of dollars in energy costs annually. By balancing the initial investment against potential savings and efficiency gains, organizations can make informed decisions that enhance their budgetary outcomes while optimizing operational performance.

The landscape of hydraulic power units is evolving rapidly, influenced by trends in technology and industrial applications. As noted in recent industry reports, innovations in hydraulic systems are increasingly focusing on efficiency and sustainability. A comprehensive analysis indicates a growing preference for electric and hybrid power units, which utilize advanced control systems to optimize energy consumption. These trends align with the findings of the 2024 China's AIGC Innovation Development Forum, which emphasized the role of next-generation models in enhancing productivity across various sectors.

Moreover, a report from Deloitte illustrates that the integration of smart technologies and eco-friendly practices in hydraulic systems could lead to significant gains in operational performance. For instance, industries leveraging intelligent hydraulic power units are expected to see a 20% increase in efficiency and a 15% reduction in maintenance costs over the next five years. This shift towards innovation not only reflects the industry's commitment to productivity but also highlights a broader adaptation to market changes, ensuring that hydraulic solutions remain competitive and relevant in the face of increasing demands for sustainable practices.