Empowering Engineering Excellence: Innovate, Elevate, Deliver.

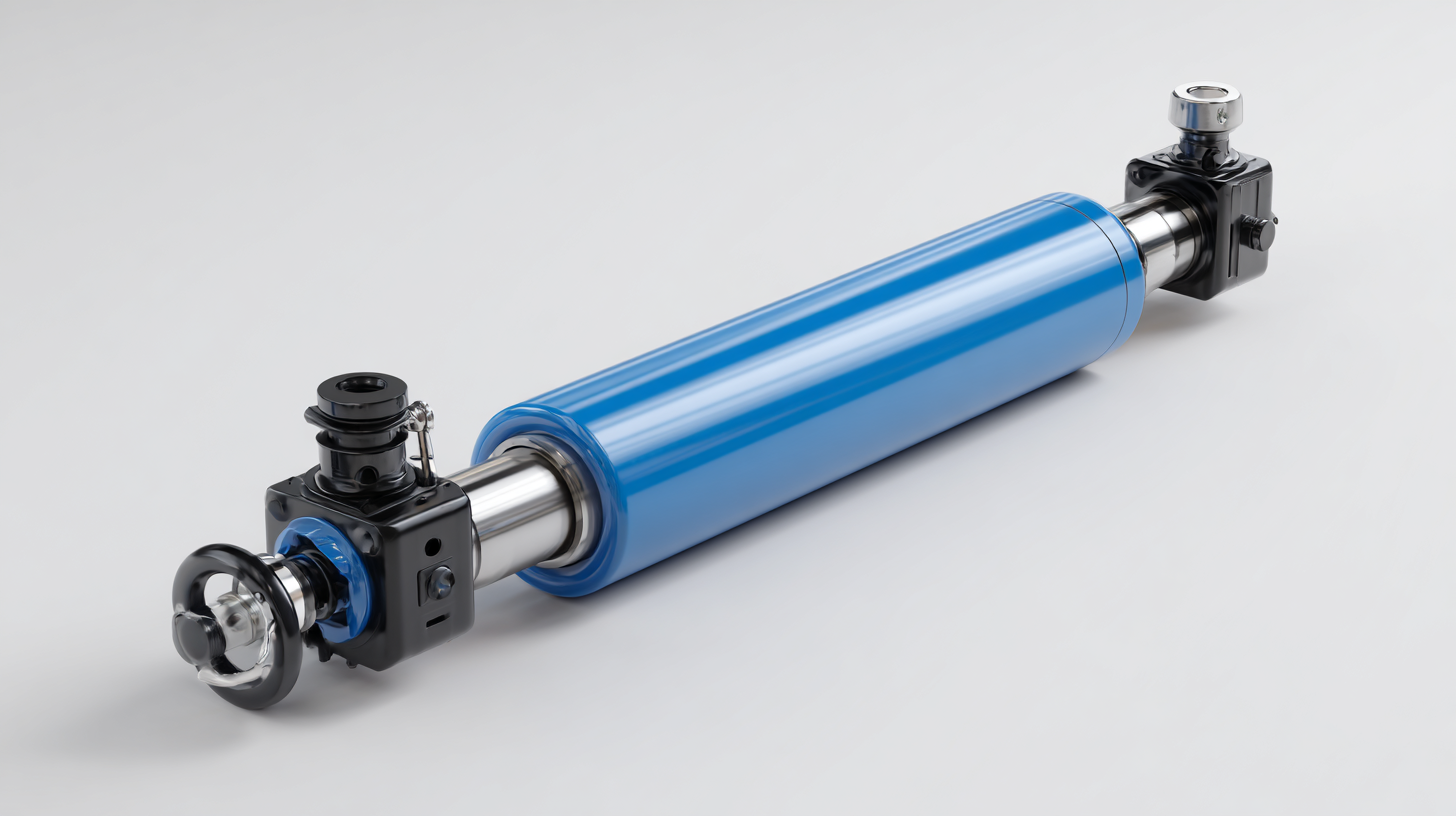

In the realm of heavy machinery and industrial applications, the Single Acting Hydraulic Cylinder stands out as a pivotal component, renowned for its efficiency in driving linear motion powered by hydraulic pressure. According to a recent industry report by MarketsandMarkets, the hydraulic cylinder market is projected to reach $6.6 billion by 2025, with significant growth driven by increased demand across sectors like construction, manufacturing, and automotive.

While Single Acting Hydraulic Cylinders are celebrated for their simplicity and reliability, exploring alternative options can provide unique benefits tailored to specific project needs.

This blog aims to delve into the top alternatives available, highlighting their distinctive advantages and applications, offering readers valuable insights to enhance their project planning and execution.

In the realm of heavy machinery and industrial applications, the Single Acting Hydraulic Cylinder stands out as a pivotal component, renowned for its efficiency in driving linear motion powered by hydraulic pressure. According to a recent industry report by MarketsandMarkets, the hydraulic cylinder market is projected to reach $6.6 billion by 2025, with significant growth driven by increased demand across sectors like construction, manufacturing, and automotive.

While Single Acting Hydraulic Cylinders are celebrated for their simplicity and reliability, exploring alternative options can provide unique benefits tailored to specific project needs.

This blog aims to delve into the top alternatives available, highlighting their distinctive advantages and applications, offering readers valuable insights to enhance their project planning and execution.

When selecting a hydraulic cylinder for your projects, there are several key factors to consider to ensure you choose the right one. First, analyze the load requirements; understanding the weight and force needed helps determine the cylinder's size and power. Also, consider the operating environment. Will the cylinder be exposed to harsh conditions like extreme temperatures or corrosive substances? This can affect the material selection and overall durability of the cylinder.

Additionally, it's important to evaluate the stroke length and mounting options. The stroke should match your application’s movement needs, while the mounting style can impact how well the cylinder performs in your setup. Always check compatibility with existing systems to avoid installation issues.

**Tip:** Always consult with the manufacturer’s specifications for pressure ratings and duty cycles; overloading a cylinder can lead to failure.

**Tip:** Consider modular designs that allow for easier maintenance and replacement of components, reducing downtime during your projects.

| Cylinder Type | Max Pressure (psi) | Bore Diameter (inches) | Stroke Length (inches) | Weight (lbs) | Application Suitability |

|---|---|---|---|---|---|

| Compact Hydraulic Cylinder | 3000 | 2.0 | 12 | 15 | Material Handling |

| Pneumatic Cylinder | 150 | 3.0 | 10 | 10 | Light Assembly |

| Double Acting Cylinder | 2500 | 4.0 | 16 | 25 | Construction Equipment |

| Telescoping Cylinder | 3500 | 3.5 | 20 | 35 | Heavy Lifting |

| Hydraulic Jack | 5000 | 5.0 | 8 | 30 | Automotive Repair |

When it comes to choosing hydraulic cylinders for various projects, understanding the differences between single acting and double acting hydraulic cylinders is crucial. Single acting cylinders utilize hydraulic pressure to extend the piston in one direction, relying on gravity or an external force for retraction. This design is simpler and typically more cost-effective, making it ideal for applications where the load can return the piston to its starting position without additional assistance. However, they may not be suitable for all tasks, especially those involving high precision or repeated movements.

On the other hand, double acting hydraulic cylinders provide power to extend and retract the piston, resulting in greater control and efficiency. This type offers more versatility as it can perform tasks in both directions with the same level of force, which is particularly beneficial for heavy-duty applications.

As the global hydraulic cylinders market is projected to grow significantly, understanding these fundamental differences can help project managers select the right type of cylinder, ensuring optimal performance and efficiency in their hydraulic systems. The ongoing advancements in energy-efficient designs also promise to enhance the effectiveness of both single and double acting systems, accommodating the rising demand for environmentally friendly solutions in industrial applications.

Hydraulic cylinders are integral to various industrial applications, and exploring alternatives to traditional single-acting models can reveal insights into performance metrics such as efficiency and load capacity. Recent studies indicate that energy efficiency in hydraulic systems is increasingly vital, with focus shifting towards reducing power losses in energy conversion and improving the integration of electric prime movers. In applications where hydraulic performance must be maximized, hybrid systems that blend hydraulic and electric technologies are proving to be effective. For instance, implementing electrification in hydraulic machinery can lead to significant improvements in operational efficiency and decreased emissions.

A notable performance metric for these alternatives involves load capacity, which is paramount for off-road hydraulic machines. A critical review emphasizes the importance of designing energy-efficient and low-pollutant machines. According to industry reports, these modern hydraulic systems can achieve load capacities exceeding 75% of conventional models while minimizing overall environmental impact. Additionally, advancements in predictive modeling using artificial neural networks are providing insights into system efficiencies, highlighting the potential for enhanced performance monitoring and environmental compliance. Emphasizing these metrics, the exploration of alternatives to traditional hydraulic cylinders reflects a broader trend toward sustainability and operational excellence in the hydraulic industry.

When evaluating budget-friendly alternatives to the best single acting hydraulic cylinders, it is essential to consider both cost and performance. Hydraulic cylinders are crucial in various projects where lifting, pushing, or pulling is required. However, not all hydraulic cylinders are created equal, and some alternatives provide similar functionality at a fraction of the cost. Exploring options such as lightweight aluminum models or smaller, compact hydraulic cylinders can yield significant savings without compromising on efficiency.

In addition to exploring alternatives, evaluating the long-term benefits of these budget-friendly options can lead to better investment choices. For instance, while a lower-priced hydraulic cylinder may seem appealing, assessing factors such as durability, maintenance costs, and operational efficiency is vital. Investing in a more affordable but robust hydraulic solution can deliver significant cost savings over time. By thoroughly analyzing these elements, project managers can ensure they select hydraulic cylinders that meet their needs while staying within budget constraints.

When considering alternatives to the best single acting hydraulic cylinder, it's essential to highlight real-world applications that illustrate the effectiveness and versatility of these systems. For instance, in the construction industry, companies have successfully integrated double acting cylinders to enhance precision in heavy lifting tasks. These cylinders allow for better control during the lowering process, minimizing the risk of accidents and ensuring that loads are handled safely and efficiently. A prominent construction firm reported a significant reduction in project completion time by switching to these hydraulic systems, showcasing the impact of choosing the right equipment.

Another area where alternative hydraulic systems have excelled is in manufacturing automation. A success story from a leading automotive manufacturer highlights their transition from traditional single acting cylinders to pneumatic alternatives. This shift enabled the facility to achieve faster cycle times and reduced energy consumption, a crucial factor in today's eco-conscious market. Additionally, the flexibility offered by pneumatic systems facilitated easier integration with robotic technologies, allowing for more streamlined production lines. These examples exemplify how exploring alternatives can lead to innovative solutions that not only enhance productivity but also promote sustainability in various industries.