Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In the world of lifting solutions, the demand for efficient and compact machinery has never been higher, with the global hydraulic jack market expected to reach a staggering $4 billion by 2025, driven by advancements in technology and increasing applications across various industries. Among these lifting tools, the "Small Hydraulic Jack" has emerged as a dominant player in 2023, offering essential advantages that cater to both industrial and residential needs.

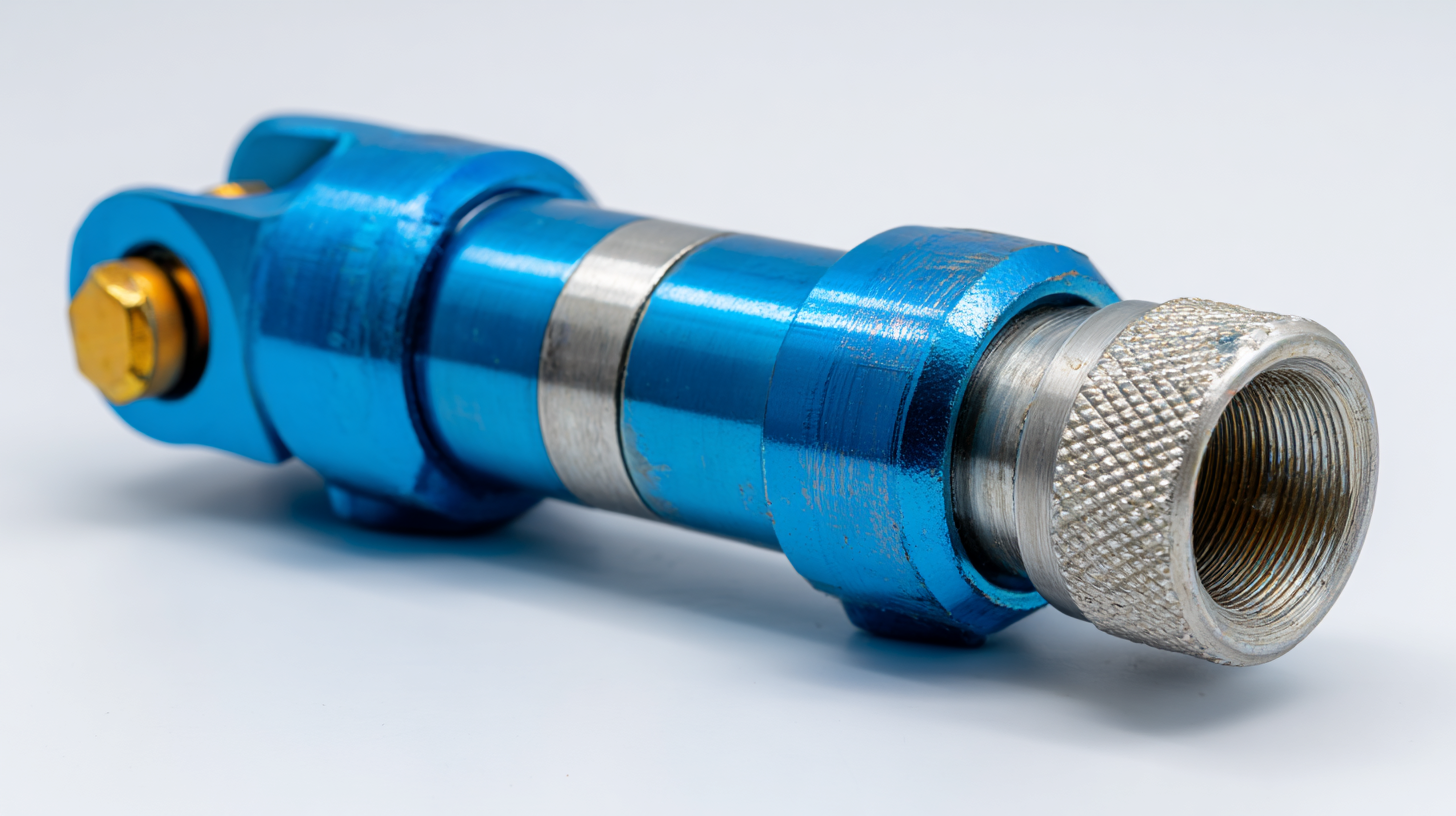

These compact devices are not only lightweight and easily portable, but they also ensure high lifting capacities and precise control, making them indispensable for tasks ranging from automotive repairs to heavy machinery maintenance. As consumers prioritize efficiency and effectiveness, the versatility and performance of small hydraulic jacks position them as the go-to solution for modern lifting challenges, highlighting their critical role in the evolving landscape of lifting technology.

These compact devices are not only lightweight and easily portable, but they also ensure high lifting capacities and precise control, making them indispensable for tasks ranging from automotive repairs to heavy machinery maintenance. As consumers prioritize efficiency and effectiveness, the versatility and performance of small hydraulic jacks position them as the go-to solution for modern lifting challenges, highlighting their critical role in the evolving landscape of lifting technology.

The growing demand for small hydraulic jacks in 2023 is driven by their versatility and efficiency in various lifting applications. As industries continue to prioritize compact and powerful tools, small hydraulic jacks have emerged as a preferred choice for both professionals and DIY enthusiasts. These jacks are not only lightweight and portable, but they also provide impressive lifting capacities, allowing users to accomplish tasks with ease.

Tip: When selecting a small hydraulic jack, always consider the weight limit it can handle. Knowing the exact load you need to lift will help ensure you choose a jack that will perform reliably and safely.

Furthermore, the ease of use of these hydraulic jacks has contributed significantly to their popularity. Many modern designs feature ergonomic handles and quick-release mechanisms that simplify operation. This makes them ideal for use in tight spaces or for jobs that require frequent lifting and lowering.

Tip: Regular maintenance is key to prolonging the life of your hydraulic jack. Ensure that you check for any leaks and keep the hydraulic fluid topped up to maintain optimal performance.

Small hydraulic jacks are gaining traction across various industries due to their unique advantages over alternative lifting solutions.

One key advantage is their compact size, which allows them to operate in tight spaces where larger lifting devices cannot. This capability is particularly beneficial in the automotive and construction sectors, where maneuverability and efficiency are paramount. Additionally, the hydraulic mechanism enables these jacks to lift significantly heavier loads compared to mechanical counterparts, enhancing productivity without sacrificing safety.

Small hydraulic jacks are gaining traction across various industries due to their unique advantages over alternative lifting solutions.

One key advantage is their compact size, which allows them to operate in tight spaces where larger lifting devices cannot. This capability is particularly beneficial in the automotive and construction sectors, where maneuverability and efficiency are paramount. Additionally, the hydraulic mechanism enables these jacks to lift significantly heavier loads compared to mechanical counterparts, enhancing productivity without sacrificing safety.

Another important benefit of small hydraulic jacks is their ease of use. Unlike manual jacks that require physical strength and effort, hydraulic jacks operate via a push-button mechanism, making them accessible to workers with varying skill levels. This simplicity not only streamlines operations but also reduces the risk of workplace injuries associated with manual lifting. Furthermore, the durability and reliability of hydraulic systems provide long-term cost savings by minimizing maintenance needs and extending service life. As industries continue to evolve, small hydraulic jacks are solidifying their role as a preferred lifting solution, adapting to the demands of modern workflows.

In 2023, the market for small hydraulic jacks has witnessed significant growth, driven by their versatility and efficiency in various applications. Industry data indicates that adoption rates have surged as more businesses recognize the advantages of integrating these compact solutions into their operations. Many sectors, from automotive repair to construction, have found that small hydraulic jacks offer the perfect balance of power and portability, making them invaluable tools that enhance productivity and safety.

When using small hydraulic jacks, consider these tips to maximize their effectiveness. Always ensure you're selecting the right jack for your specific task; knowing the weight and lifting height required can prevent accidents and equipment failures. Additionally, regular maintenance is crucial—check hydraulic fluid levels and inspect parts for wear and tear, ensuring seamless performance.

Another important aspect is operator training. While small hydraulic jacks are user-friendly, proper education on their use can significantly reduce risks and improve efficiency. Educate your team about load limits and safety protocols to ensure that everyone is equipped to handle these powerful tools responsibly. This focus on training and maintenance will not only enhance safety but also increase the longevity of your hydraulic jacks.

In the competitive landscape of lifting solutions, small hydraulic jacks stand out for their efficiency, portability, and cost-effectiveness compared to other options. A recent analysis reveals that small hydraulic jacks offer a lifting capacity that typically ranges from 1.5 to 3 tons, making them ideal for automotive maintenance and household tasks. Their compact design allows users to easily maneuver them in tight spaces where larger jacks fall short, showcasing a critical advantage that customers increasingly favor in 2023.

Furthermore, industry reports indicate that small hydraulic jacks have gained significant traction due to advancements in hydraulic technology, resulting in improved reliability and faster lifting times. While premium floor jacks may offer higher capacities or extended reach, they often come with a steep price tag—sometimes upwards of $400. In contrast, small hydraulic jacks provide a budget-friendly solution without compromising performance, appealing to both amateur car enthusiasts and professional mechanics alike. This balance of functionality and affordability is driving the preference for small hydraulic jacks in today's lifting solutions market.

In 2023, small hydraulic jacks are experiencing significant innovations that enhance their applications in various industries. Recent developments show a trend towards creating portable devices, which are essential for improving tasks such as adjusting rail car coupling heights. This evolution of technology not only increases efficiency but also optimizes safety protocols, allowing operators to perform adjustments quickly and accurately.

Tips for maximizing the utility of small hydraulic jacks include proper maintenance and regular inspections to ensure they operate flawlessly. Additionally, utilizing the right lifting techniques can prevent damage to both the jack and the load, providing a safer work environment. As small hydraulic jacks become more efficient, industries should stay informed about the latest advancements to leverage these tools effectively in their operations.

Moreover, emerging tech trends are paving the way for greater adaptability and versatility of small hydraulic jacks. As new models become available, features such as enhanced portability and user-friendly interfaces will empower workers to tackle lifting tasks with ease. Embracing these innovations is crucial for businesses aiming to stay competitive in a rapidly evolving landscape.

| Reason | Description | Application Fields | Future Trends |

|---|---|---|---|

| Compact Size | Small hydraulic jacks are designed to be portable and easy to handle. | Automotive repair, Maintenance works | Increased miniaturization for various applications. |

| High Load Capacity | Despite their small size, they can lift substantial weights efficiently. | Construction, Industrial machinery | Innovations in materials increasing lifting capabilities. |

| Ease of Use | User-friendly design allows for quick setup and operation. | Home DIY projects, Workshops | Integration of smart features for better usability. |

| Safety Features | Incorporation of safety valves and overload protection systems. | Emergency services, Aircraft maintenance | Advanced safety technologies for operators. |

| Versatility | Can be used for different lifting applications across multiple sectors. | Manufacturing, Warehousing | Customizable options for varied applications. |

| Cost-Effectiveness | Affordable price point makes them accessible for small businesses. | Small businesses, Retail | Emerging market opportunities for cost-effective solutions. |

| Innovative Materials | Use of lightweight, high-strength materials improves performance. | Automotive, Aerospace | Development of new composites and alloys. |

| Environmental Impact | Designed with eco-friendly materials and energy-efficient mechanisms. | Green construction, Maintenance of renewable energy systems | Shift towards sustainability in manufacturing processes. |