Empowering Engineering Excellence: Innovate, Elevate, Deliver.

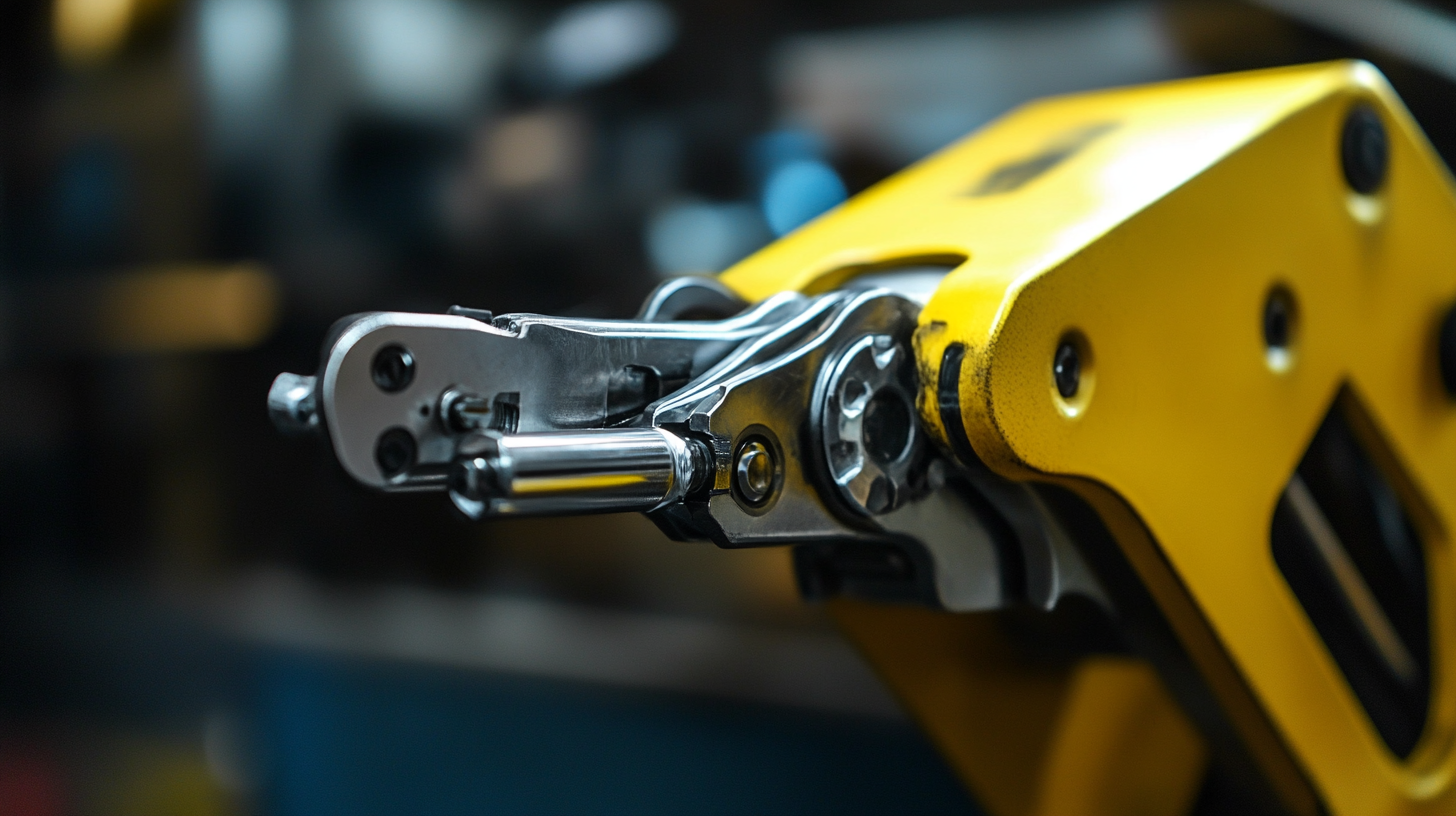

When investing in a Hydraulic Crimping Tool, understanding the intricacies of after-sales service and repair costs can significantly enhance your overall experience and investment return. This essential piece of equipment is vital for manufacturers and contractors who rely on precision and reliability for their projects.

When investing in a Hydraulic Crimping Tool, understanding the intricacies of after-sales service and repair costs can significantly enhance your overall experience and investment return. This essential piece of equipment is vital for manufacturers and contractors who rely on precision and reliability for their projects.

However, the importance of selecting the right tool extends beyond the initial purchase; it includes evaluating how well the manufacturer supports its product after the sale. By employing our seven essential tips, you can navigate the often-overlooked aspects of after-sales service, ensuring that your Hydraulic Crimping Tool remains operational for years to come.

This guide will help you make informed decisions that not only maximize your investment but also enhance your productivity and peace of mind in the field.

When investing in hydraulic crimping tools, understanding the importance of after-sales service is crucial for long-term satisfaction and performance. After-sales service entails support provided to customers following their purchase, ensuring that any issues faced with the tool can be quickly addressed. This is particularly significant with hydraulic tools, where precision and safety are paramount. A reliable after-sales service guarantees not just prompt repairs but also essential maintenance tips to maximize the efficiency and lifespan of the equipment.

Moreover, the repair costs associated with hydraulic crimping tools should be a key consideration when evaluating after-sales service. Tools prone to frequent breakdowns can lead to escalating repair costs, undermining your initial investment. A good after-sales program will include warranties, accessible spare parts, and expert assistance to help users tackle repairs effectively. By prioritizing after-sales service and understanding its value, users can minimize downtime, reduce unexpected expenses, and ensure their hydraulic crimping tools operate at peak performance throughout their lifecycle.

When it comes to hydraulic crimping tools, understanding the key factors that affect repair costs is crucial for maximizing your investment. One primary factor is the frequency of use; according to industry reports, tools that are used daily may require repairs 30% more often than those used weekly. Regular wear and tear can lead to more frequent breakdowns, which directly impacts repair costs over time.

Another significant factor is the quality of the tool itself. A study by the Hydraulic Tools Association reveals that premium brands often incur 20-40% lower repair costs compared to lower-tier models, as higher-quality materials and engineering contribute to enhanced durability and reliability. Additionally, the availability of replacement parts plays a vital role. Tools from manufacturers with easy access to spare parts and efficient service networks can often be repaired quicker and at a lower cost, keeping downtime to a minimum.

Lastly, proper maintenance practices can greatly influence repair expenses. The same study indicates that regular maintenance can reduce repair costs by up to 50%, making it essential for users to establish a routine check-up and care schedule for their hydraulic crimping tools. By focusing on these factors, users can better manage and mitigate repair costs, ultimately enhancing the longevity and performance of their equipment.

Regular maintenance is crucial for minimizing long-term repair costs, particularly for hydraulic crimping tools. Just as vehicles from brands with low maintenance costs tend to enjoy significant financial perks, the same principle applies to tools. According to industry insights, proactive servicing can lead to up to a 30% reduction in repair expenses over the tool’s lifespan. Investing in scheduled maintenance ensures that minor issues are addressed before they escalate into costly repairs.

To maximize your investment, consider these essential tips: First, keep a maintenance log to track services and repairs performed. This can help identify patterns that may indicate underlying issues, thus preventing unexpected breakdowns. Second, use quality replacement parts to maintain efficiency and extend the tool's lifespan. Data sourced from reports indicate tools using high-quality components experience fewer malfunctions, contributing to lower overall repair costs. By implementing these strategies, you can ensure your hydraulic crimping tool remains in optimal condition, ultimately saving you money and enhancing productivity in the long run.

| Tip | Description | Expected Cost Savings (%) | Frequency of Maintenance |

|---|---|---|---|

| Regular Cleaning | Remove debris and contaminants to prevent corrosion. | 15% | Monthly |

| Lubrication | Use high-quality lubricants to reduce friction. | 20% | Bi-Monthly |

| Component Inspection | Check for wear and tear on critical components. | 25% | Quarterly |

| Calibration | Ensure accurate pressure readings and performance. | 30% | Semi-Annually |

| Proper Storage | Store tools in dry, clean, and temperature-controlled environments. | 10% | Every Use |

| Training Operators | Educate users on proper tool handling and maintenance. | 40% | Annually |

| Scheduled Professional Servicing | Regular professional check-ups to identify issues early. | 50% | Annually |

When investing in a hydraulic crimping tool, one of the most critical factors to consider is the quality of after-sales support. According to a study by the Manufacturing Industry Institute, nearly 70% of manufacturing professionals reported that inadequate after-sales service leads to increased downtime and associated costs. To mitigate these risks, buyers should prioritize features that enhance after-sales support.

First, responsive technical support is essential. A tool that comes with a dedicated support team, available for quick consultations and problem resolution, can significantly reduce operational hiccups. Research from the National Association of Manufacturers highlights that businesses with robust support systems experience 40% less equipment downtime, which translates into substantial savings over time.

Another important feature is the availability of replacement parts and repair services. A report by the Service Industry Association found that companies offering immediate access to spare parts can minimize repair times by up to 50%. This not only helps in maintaining productivity but also enhances the overall return on investment. Lastly, warranty coverage details should be thoroughly examined; tools with extended warranties often indicate confidence in the product's durability, providing users with peace of mind as they navigate their operational challenges.

Investing in high-quality hydraulic crimping tools is essential for maximizing cost efficiency and minimizing long-term expenses. According to a report by Research and Markets, the global hydraulic tools market is projected to grow significantly, driven by the increasing demand for efficient and durable equipment across various industries. Quality brands not only provide reliable products but also offer comprehensive after-sales service, which can significantly reduce repair costs over time.

When you choose reputable brands, you're also likely to benefit from better warranty terms and access to genuine replacement parts, which enhances the longevity and performance of your tools. A study from the International Journal of Advanced Manufacturing Technology reveals that using high-quality tools can improve operational efficiency by up to 30%. By investing in well-regarded brands, not only do customers enjoy the peace of mind that comes with superior reliability, but they also align their expenditures with long-term savings, ultimately boosting their return on investment in the manufacturing process.