Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In today's fast-paced manufacturing environment, maximizing efficiency is crucial for staying competitive, and a Hydraulic Press Machine can play a pivotal role in achieving this goal. This powerful tool is designed to apply pressure for a variety of applications, from shaping and molding materials to assembling components with precision. By understanding how to optimize the use of a Hydraulic Press Machine, manufacturers can streamline their production processes, reduce waste, and improve overall productivity.

This guide will explore effective strategies for integrating this machinery into your operations, addressing key factors such as maintenance, setup efficiency, and operator training. Whether you are a seasoned professional or new to the world of hydraulic pressing, leveraging the capabilities of a Hydraulic Press Machine can significantly enhance your production efficiency and drive your business forward.

When selecting a hydraulic press machine, key features can significantly enhance your production efficiency. First and foremost, consider the machine's tonnage capacity. It should be capable of handling the specific materials and tasks your production line demands. A machine with adjustable tonnage allows for greater flexibility, enabling operators to perform various tasks without compromising on performance.

Another vital feature is the speed of operation; a hydraulically powered system should strike a balance between force and speed to optimize cycle times. Look for machines equipped with a rapid approach feature, which can minimize the time it takes to position materials before the actual pressing occurs. Additionally, automation capabilities, such as programmable logic controllers (PLCs), can streamline operations by reducing manual intervention and errors, leading to a more efficient workflow.

Finally, pay attention to the safety features integrated into the hydraulic press machine. Emergency stop buttons, safety guards, and pressure relief valves are essential for protecting operators and maintaining a safe working environment. A machine designed with robust safety protocols will not only help in compliance with industry standards but also increase overall productivity by reducing downtime due to accidents or malfunctions.

| Feature | Description | Importance | Example Specifications |

|---|---|---|---|

| Pressure Capacity | The maximum pressure the press can apply, usually measured in tons. | Essential for determining the machine's ability to handle different materials. | 5-200 tons |

| Stroke Length | The maximum distance the ram can travel during operation. | Affects material thickness and overall versatility of press work. | 20-600 mm |

| Cycle Time | The time it takes to complete one full pressing cycle. | Shorter cycle times increase productivity. | 30-120 seconds |

| Control System | The method used to operate the hydraulic press, such as manual, semi-automatic, or fully automatic. | Automation can enhance efficiency and reduce labor costs. | PLC, touchscreen controls |

| Safety Features | Incorporates protective elements to ensure operator safety. | Crucial for compliance with industry regulations. | Emergency stop, safety guards |

| Energy Efficiency | The power consumption of the machine during operation. | Lower energy costs enhance overall operational efficiency. | Variable displacement pumps |

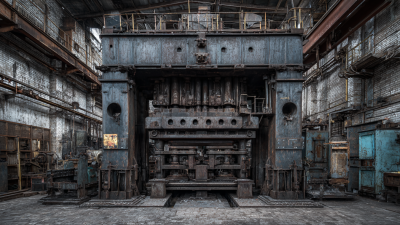

Optimizing the workspace layout for a hydraulic press machine is crucial to maximizing both efficiency and safety in the production process. A well-organized workspace not only streamlines operations but also minimizes unnecessary movements, which can lead to time and energy loss. Placing the hydraulic press in a central location allows for easier access to raw materials and finished products, reducing the distance operators need to travel. Additionally, ensuring that all necessary tools and equipment are within arm's reach can significantly enhance workflow and reduce downtime.

Moreover, incorporating designated zones for various tasks—such as material handling, assembly, and maintenance—can further optimize the workspace. This zoning strategy helps to delineate areas for different functions, minimizing clutter and potential hazards. Ensuring adequate space around the hydraulic press for safe maneuverability is also essential; this not only protects operators but also enhances overall productivity. By fostering an environment that prioritizes accessibility and organization, businesses can leverage their hydraulic press machines more effectively, leading to improved output and reduced operational costs.

When operating a hydraulic press machine, proper loading techniques are crucial for maximizing efficiency and ensuring safety. First, always ensure that the material being processed is clean and free from contaminants. This not only prevents damage to the press but also enhances the quality of the final product. When loading, position the material evenly on the press bed to distribute the force uniformly. This reduces the risk of warping and ensures a more consistent outcome. Additionally, use fixtures or supports as needed to stabilize the material and prevent movement during the pressing operation.

During operation, it’s essential to monitor the press closely. Operators should familiarize themselves with the machine's controls and establish a routine for checking hydraulic fluid levels and system integrity before each use. Implementing a step-by-step checklist can help maintain operational standards and safety protocols. Furthermore, train staff to recognize the sounds and movements of the machine during operation, as abnormalities might indicate potential issues. Consistent assessment and adherence to these best practices not only enhance the efficiency of the hydraulic press but also contribute to a safer working environment for all personnel involved.

Routine maintenance is essential for maximizing the efficiency and longevity of a hydraulic press machine in any production process.

Regularly scheduled inspections and servicing can help identify potential issues before they escalate,

ensuring that the machine operates at peak performance.

Checking fluid levels, replacing worn seals, and cleaning filters are just a few critical tasks that should be prioritized.

By following a maintenance schedule, operators can minimize downtime caused by unexpected breakdowns, thus maintaining a smooth production flow.

Furthermore, implementing a system for tracking maintenance activities can also enhance durability.

Keeping detailed records of maintenance tasks performed, along with the machine's performance metrics, allows for proactive adjustments and refinements.

This data-driven approach not only helps in scheduling future maintenance but also aids in identifying patterns that might suggest necessary operational changes.

By investing time and resources into regular upkeep, businesses can ensure that their hydraulic press machines run efficiently,

ultimately supporting a more productive and sustainable manufacturing environment.

Integrating automation into your production process with a hydraulic press machine can significantly streamline operations and boost overall efficiency. By implementing automated systems, you can reduce manual labor, minimize human error, and enhance production speed. Automation allows for precise control over the pressing process, ensuring consistent quality and reducing the time spent on each cycle.

Tips: Start by evaluating your current production workflow to identify areas where automation can be integrated. Look for solutions such as programmable logic controllers (PLCs) that can optimize the hydraulic press’s operation. Additionally, consider investing in sensors and monitoring systems to provide real-time feedback on machine performance, which can further enhance efficiency.

Another key aspect is training your team to work alongside automated systems. Ensure that staff members are equipped with the necessary skills to operate and troubleshoot automated machinery. Regular training sessions can improve confidence and productivity, leading to a more efficient production environment where everyone is aligned with the automated processes in place.