Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In modern engineering applications, the Hydraulic Ram Cylinder plays a pivotal role in enhancing the efficiency and effectiveness of various mechanical systems. As highlighted by the Industry Research Group, the global hydraulic cylinder market is projected to reach approximately $23.5 billion by 2025, with hydraulic ram cylinders representing a significant portion of this growth due to their versatility in multiple sectors such as construction, manufacturing, and marine operations. These hydraulic systems are essential in applications requiring powerful force and precise control, where standard mechanical methods may fall short. Furthermore, advancements in technology have led to the evolution of hydraulic ram cylinders, increasing their reliability and operational capability. As industries continue to seek solutions for more efficient power transmission, understanding the fundamental principles and applications of hydraulic ram cylinders becomes essential for engineers and industry professionals alike.

Hydraulic ram cylinders play a crucial role in modern engineering applications by translating hydraulic pressure into linear motion. Understanding the key principles of their functionality is essential for optimizing performance in various sectors, including construction and agriculture. These cylinders operate based on Pascal’s law, which states that pressure applied to a confined fluid is transmitted evenly in all directions. This principle allows hydraulic systems to lift heavy loads with minimal effort, making them indispensable in equipment that demands high force output.

Recent advancements in electro-hydraulics have further improved the efficiency and control of hydraulic ram cylinders, particularly in off-highway vehicles. With enhanced machine control capabilities, these systems facilitate precise movements and operational efficiency, leading to better overall performance. Additionally, maintaining the integrity of hydraulic fluids is vital; contamination from particles can severely hinder functionality. Implementing effective filtration systems ensures that hydraulic and lubricating oils remain clean, thereby prolonging the lifespan of hydraulic components and enhancing operational reliability in engineering applications.

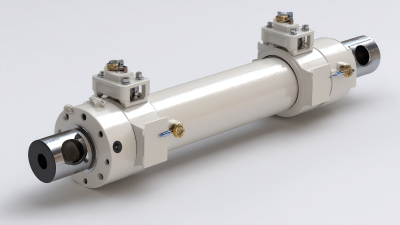

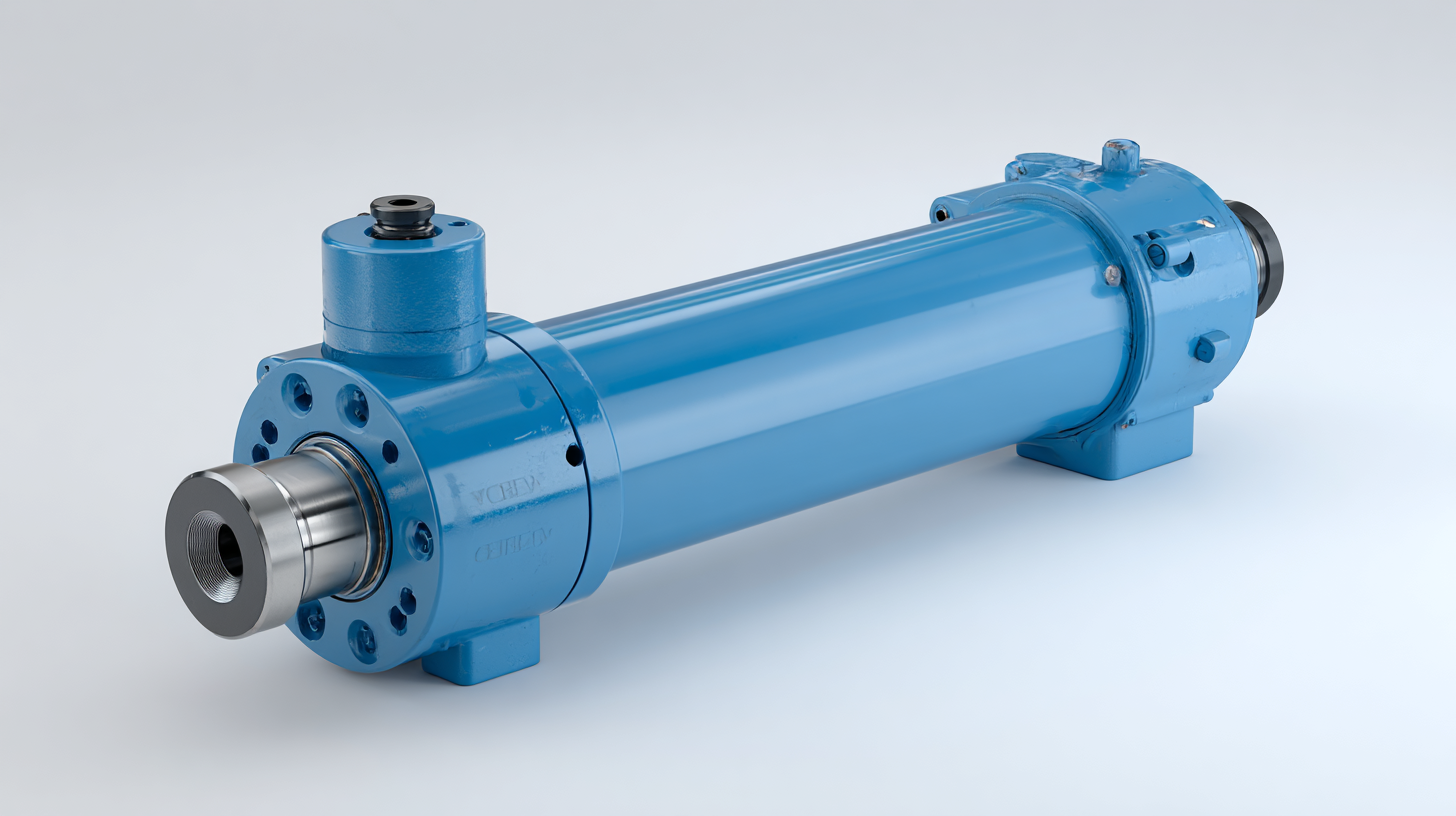

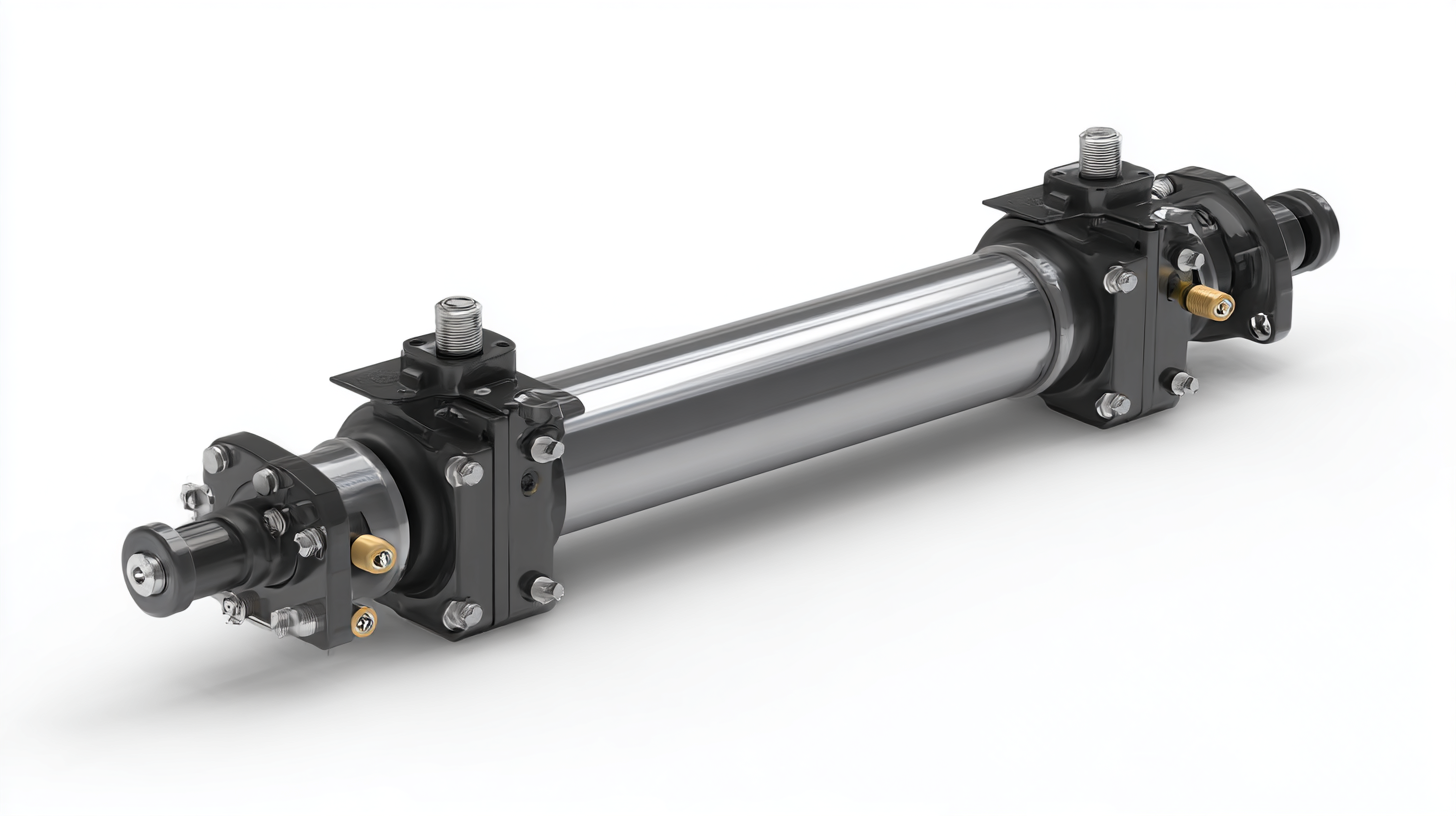

Hydraulic ram cylinders are crucial components in various engineering applications, and they come in a variety of types, each designed for specific functions. One of the most common types is the double-acting hydraulic ram cylinder. This design allows fluid to act on both sides of the piston, providing a force in both extension and retraction, making it suitable for tasks requiring consistent power in both directions, such as in hydraulic presses and machinery.

Another important type is the single-acting hydraulic ram cylinder. Unlike its double-acting counterpart, this cylinder operates with hydraulic pressure applied to one side of the piston only, utilizing gravity or a spring for the return stroke. This design is typically more cost-effective and simpler, making it ideal for applications like lifting mechanisms and compacting machines. Additionally, specialized variations such as telescopic cylinders are designed to extend longer distances while maximizing compactness, often used in dump trucks and construction equipment. Understanding these different types allows engineers to choose the most appropriate hydraulic ram cylinder for their specific applications, enhancing efficiency and performance across various industries.

Another important type is the single-acting hydraulic ram cylinder. Unlike its double-acting counterpart, this cylinder operates with hydraulic pressure applied to one side of the piston only, utilizing gravity or a spring for the return stroke. This design is typically more cost-effective and simpler, making it ideal for applications like lifting mechanisms and compacting machines. Additionally, specialized variations such as telescopic cylinders are designed to extend longer distances while maximizing compactness, often used in dump trucks and construction equipment. Understanding these different types allows engineers to choose the most appropriate hydraulic ram cylinder for their specific applications, enhancing efficiency and performance across various industries.

When selecting the right hydraulic ram cylinder for your engineering project, understanding the specific application and performance requirements is paramount. Hydraulic cylinders are integral to converting hydraulic energy into mechanical force, and their efficiency directly impacts the overall performance of various systems. According to a report by the International Fluid Power Society, the global hydraulic cylinder market is expected to reach $18 billion by 2026, reflecting the increasing reliance on these essential components across industries such as construction, agriculture, and manufacturing.

**Tip:** Assess the load capacity, stroke length, and mounting style before making a decision. For instance, a given application may require a double-acting cylinder rather than a single-acting one, depending on the external forces at play. It's also crucial to consider environmental factors, such as temperature and exposure to corrosive substances, which can affect cylinder longevity and performance.

In addition to technical specifications, it's important to evaluate the manufacturer’s credibility and post-purchase support offerings. According to the Hydraulic Institute, choosing hydraulic components from reputable suppliers can significantly reduce the risk of operational failures. This ensures not only the quality of the product but also access to expertise in troubleshooting and maintenance, which can lead to long-term cost savings.

**Tip:** Always request data sheets and performance curves from manufacturers to compare how different models will meet the specific demands of your system. While initial costs may vary, investing in the right hydraulic ram cylinder can enhance durability and efficiency, ultimately leading to better project outcomes.

This bar chart illustrates the various applications and the corresponding capacity of hydraulic ram cylinders in modern engineering. The data highlights key applications and their usage in industries.

Proper maintenance of hydraulic ram cylinders is crucial for ensuring their longevity and efficiency in various engineering applications. Regular inspections should be conducted to check for leaks, corrosion, and signs of wear. Ensuring that all seals and components are in good condition can prevent potential failures and costly downtime. It is advisable to maintain a clean environment around hydraulic systems, as contaminants can significantly affect performance.

Additionally, regular lubrication is essential in keeping hydraulic ram cylinders operating smoothly. Using the recommended type and amount of hydraulic fluid not only enhances efficiency but also helps in reducing friction and wear on moving parts. Operators should also monitor the operating temperatures, as exceeding the recommended limits can lead to thermal degradation of both fluid and components. By adhering to these maintenance tips, the reliability and performance of hydraulic ram cylinders can be significantly maximized, ensuring optimal functionality in demanding engineering contexts.

Hydraulic ram cylinders play a crucial role in a wide range of industries, from construction to manufacturing. In the construction sector, these cylinders are integral to heavy machinery, such as excavators and bulldozers, where they provide the necessary force to lift and move heavy loads. Their efficiency and precision allow for improved safety and effectiveness on job sites, making them indispensable for any large-scale projects. The ability to exert significant force with minimal input makes hydraulic systems optimal for tasks that require both strength and control.

In the manufacturing industry, hydraulic ram cylinders are utilized in automated machinery for various processes, including pressing, clamping, and molding. These applications highlight the versatility of hydraulic systems, enabling manufacturers to increase productivity and maintain high-quality standards in their output. Additionally, in the automotive sector, hydraulic cylinders facilitate operations in assembly lines, enhancing the speed and accuracy of vehicle production. As industries continue to evolve, the importance of hydraulic ram cylinders is likely to grow, solidifying their place as vital components in modern engineering applications.