Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In the evolving landscape of heavy machinery repair, the role of Hydraulic Pullers has emerged as a critical factor for efficiency and precision. According to a recent industry report, the global hydraulic tools market is projected to reach USD 31 billion by 2025, highlighting the escalating demand for advanced repair solutions. Hydraulic Pullers are at the forefront of this trend, offering innovative designs that streamline the extraction and replacement processes for various machine components. These tools not only enhance productivity but also reduce downtime, a crucial metric as studies indicate that unscheduled machinery repairs can cost companies up to 20% of their annual revenue. As the industry seeks to maximize operational efficiency, understanding how to identify high-quality suppliers and implement top strategies for procuring Hydraulic Pullers becomes essential for businesses aiming to stay competitive in the market.

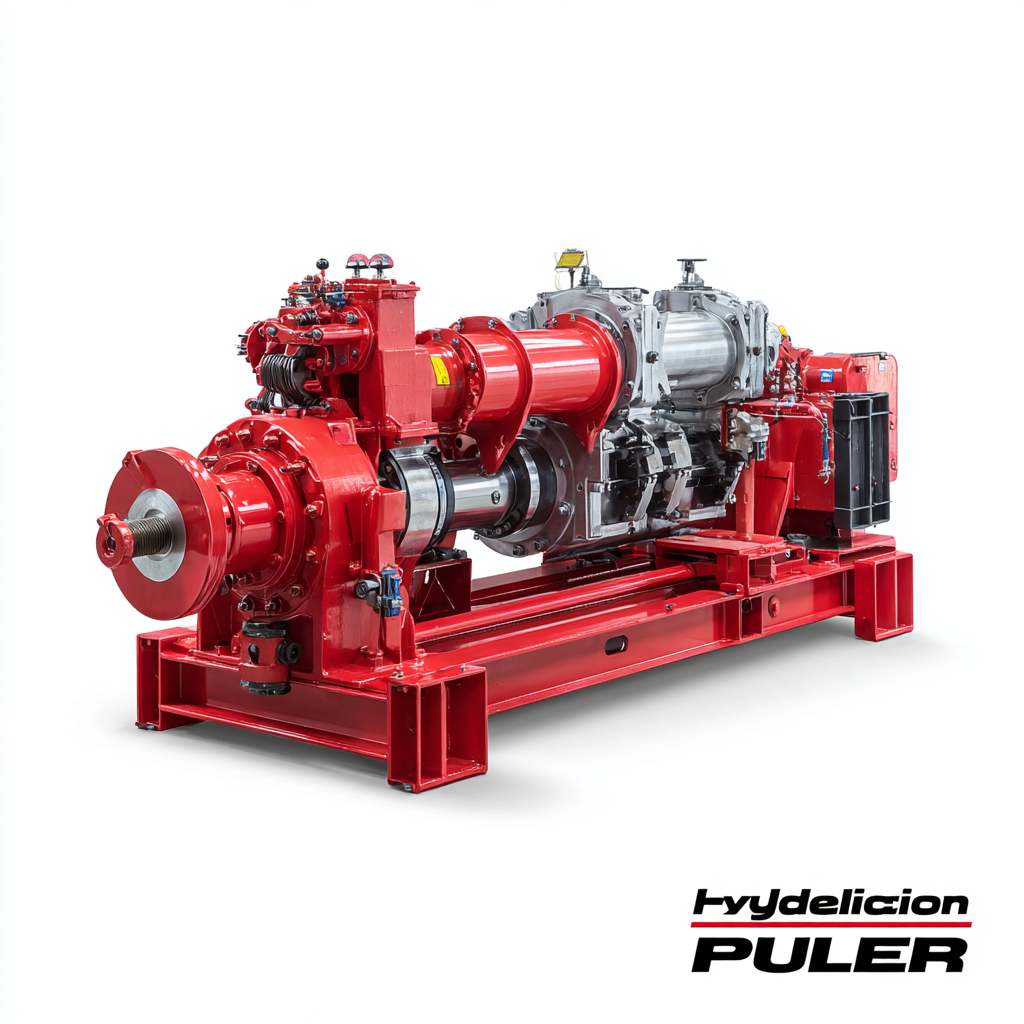

The evolution of hydraulic pullers has marked a significant turning point in heavy machinery repair solutions, offering enhanced efficiency and increased safety for technicians. Historically, repairing large machinery often involved labor-intensive and time-consuming processes, with limited tools to assist in the removal of stubborn components. However, the introduction of hydraulic pullers has revolutionized this landscape by providing a powerful means to exert even pressure on parts, reducing the risk of damage and improving overall repair times.

As technology continues to advance, so too do the innovative designs of hydraulic pullers. Modern versions incorporate features such as adjustable pulling arms, integrated safety mechanisms, and user-friendly controls, allowing for greater versatility in various applications. These advancements not only enhance the ease of operation but also empower technicians to handle complex repairs with confidence. The transition from mechanical to hydraulic solutions has thus led to a remarkable improvement in the maintenance of heavy machinery, allowing businesses to minimize downtime and optimize productivity in a competitive industry.

| Puller Type | Max Load Capacity (tons) | Application Purpose | Weight (kg) | Hydraulic Pressure (psi) | Notable Feature |

|---|---|---|---|---|---|

| Two-Jaw Puller | 10 | Bearing Removal | 8 | 4000 | Compact Design |

| Three-Jaw Puller | 15 | Gear Pulling | 12 | 6000 | 360° Grip |

| Collet Type Puller | 20 | Shaft Removal | 10 | 5000 | Quick Release |

| Specialized Hydraulic Puller | 25 | Heavy Machinery | 15 | 7000 | Adjustable Reach |

As we look ahead to 2025, the hydraulic puller technology is set to undergo significant advancements that will revolutionize the maintenance and repair of heavy machinery. One of the notable trends is the integration of smart technology into hydraulic pullers, enabling remote monitoring and diagnostics. This shift not only enhances operational efficiency but also reduces downtime, allowing technicians to swiftly address issues before they escalate. The application of IoT-enabled devices will facilitate data collection in real-time, providing valuable insights into the performance and longevity of machinery.

Another critical trend on the horizon is the development of more compact and lightweight hydraulic pullers. Manufacturers are prioritizing portability without sacrificing power, making these tools easier to transport and use in various locations. Furthermore, innovations in materials, such as advanced composites and alloys, are contributing to the durability and strength of hydraulic pullers, ensuring they can withstand the rigors of job sites. These advancements will not only improve user experience but also lead to safer operation standards in the field, aligning with growing industry demands for both efficiency and safety.

The impact of innovative hydraulic pullers on operational efficiency in heavy machinery repair solutions cannot be overstated. As industries evolve, the need for advanced tools has become critical to managing downtime and enhancing productivity. Hydraulic pullers, with their high capacity and precision, are transforming how heavy machinery repairs are conducted, streamlining processes that once took hours or even days. This shift towards innovative hydraulic solutions is particularly evident in regions where manufacturing capabilities are expanding rapidly, leading to increased operational efficiencies.

Incorporating modern hydraulic technology allows for a significant reduction in labor intensity and repair time. For instance, utilizing long-stroke single-rod hydraulic cylinders in machinery has improved lifting capabilities and reduced the risks associated with manual handling. Companies are now benefiting from the enhanced reliability and effectiveness of hydraulic systems, allowing them to focus on strategic growth rather than laborious repairs.

Tips for Maximizing Hydraulic Puller Efficiency:

Hydraulic pullers have become essential tools in the heavy machinery repair industry, providing innovative solutions for challenging tasks. Case studies featuring advanced hydraulic pullers illustrate their transformative impact on efficiency and safety in repairs. For instance, a notable case involved a mining operation where a hydraulic puller was used to remove a large gear assembly. The implementation reduced downtime significantly, allowing the team to complete repairs in a fraction of the time traditionally required. This not only improved productivity but also enhanced worker safety by minimizing the risks associated with manual removal techniques.

When working with hydraulic pullers, it's crucial to follow best practices to ensure effective results. Always assess the load capacity of the puller and choose one that matches or exceeds your needs. Additionally, consider using protective gear and ensuring the work area is clear of hazards. These tips can help prevent accidents and improve the overall repair process. Another tip is to regularly maintain and inspect your hydraulic pullers, as this can extend their lifespan and enhance performance during demanding tasks.

As industries evolve into the era of Industry 4.0, the integration of smart technologies is revolutionizing traditional processes, including heavy machinery repairs. One of the significant advancements in this realm is the development of smart hydraulic pullers. These innovative tools not only enhance the efficiency of maintenance tasks but also provide real-time data analysis, predictive maintenance capabilities, and improved operator safety. By synchronizing with IoT devices, they enable technicians to monitor equipment conditions and streamline workflow, ultimately transforming repair solutions.

The hydraulics market is poised for substantial growth, projected to reach approximately $44.26 billion by 2030. This surge indicates a growing demand for advanced hydraulic systems across various sectors, highlighting the importance of investing in smart hydraulic pullers. By embracing these technologies, businesses can enhance their operational efficiency, reduce downtime, and respond more effectively to challenges in machinery maintenance. The future of heavy machinery repair lies in leveraging smart solutions that align with Industry 4.0 principles, making hydraulic pullers a crucial component in this transformative journey.