Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In the dynamic world of hydraulic systems, selecting the right hydraulic fittings is critical for the efficiency and reliability of any project. According to Mark Johnson, a renowned expert in hydraulic engineering, "The right fittings not only enhance the performance of hydraulic systems but also ensure safety and longevity." This statement underscores the importance of understanding the various types of hydraulic fittings available on the market and how each one can impact the overall functionality of your hydraulic system.

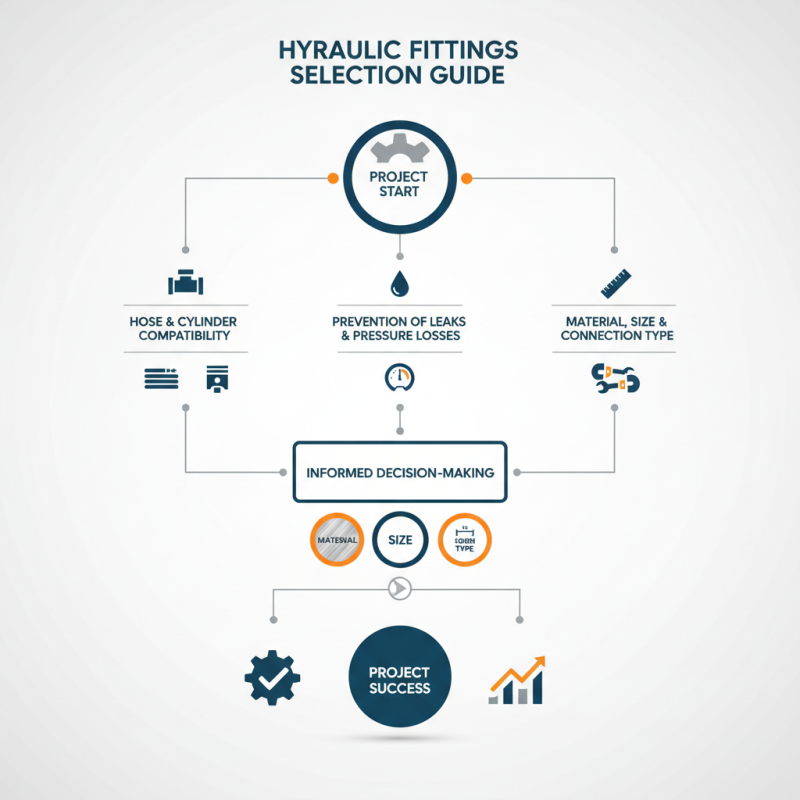

As projects become increasingly complex, the need for precise and dependable hydraulic fittings grows. From ensuring compatibility with hoses and cylinders to preventing leaks and pressure losses, the decision-making process can be overwhelming. A well-informed choice can save both time and resources, making it essential to consider factors such as material, size, and connection type. This guide will provide valuable insights into navigating the selection of hydraulic fittings, ensuring that every component of your hydraulic system works in harmony to achieve optimal results. By equipping yourself with essential knowledge, you can make informed decisions that contribute to the success of your projects.

Hydraulic fittings play a critical role in the functioning of hydraulic systems by providing the necessary connections between hoses, pipes, and cylinders. Understanding the different types of hydraulic fittings is essential for ensuring system efficiency and reliability. Common types include threaded fittings, flanged fittings, and quick-connect fittings. Each type serves a specific purpose and is designed to accommodate the unique demands of various hydraulic applications. According to a report from MarketsandMarkets, the hydraulic fittings market is projected to grow significantly, driven by increasing investments in infrastructure and industrial automation.

When selecting hydraulic fittings, one must consider factors such as compatibility with fluids, pressure ratings, and the operating environment. Materials like steel, brass, and plastic are frequently used, each offering different advantages in terms of strength, corrosion resistance, and weight. For instance, steel fittings are known for their durability and ability to withstand high pressures, while brass fittings offer excellent corrosion resistance, making them suitable for hydraulic systems exposed to harsh conditions. An analysis from Research and Markets highlights that the choice of materials influences not only the longevity of hydraulic fittings but also their overall performance in high-demand settings.

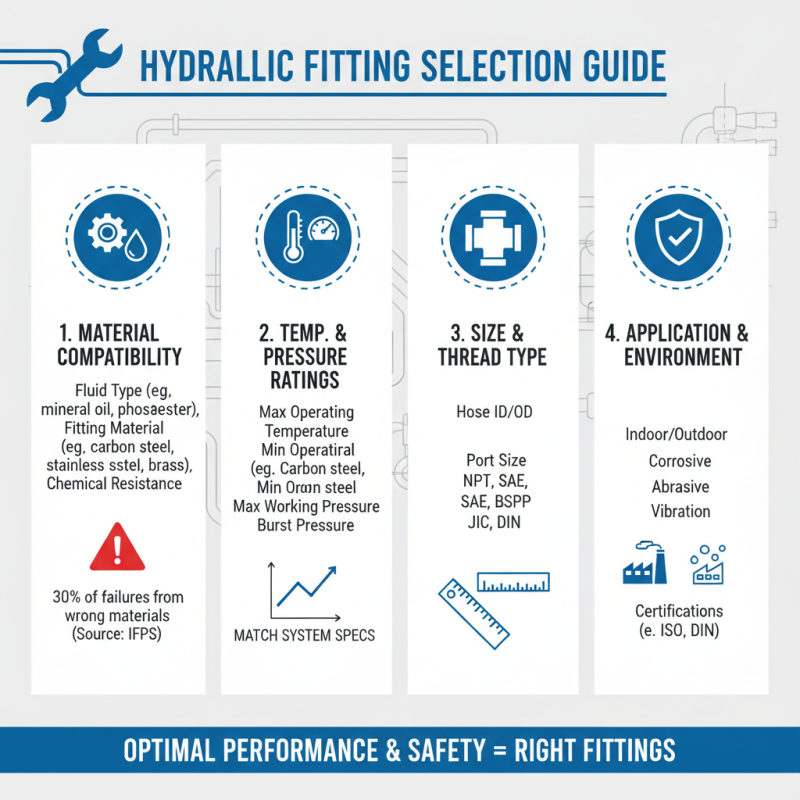

When selecting hydraulic fittings for your projects, understanding several key factors is essential for ensuring optimal performance and safety. First and foremost, the compatibility of materials between the hydraulic fluid and the fittings is crucial. According to a report by the International Fluid Power Society, nearly 30% of hydraulic system failures are attributed to inappropriate material selection. Therefore, it's vital to consider the type of hydraulic fluid being used, along with temperature and pressure ratings, to select a fitting that will withstand the working conditions without degrading over time.

Another important aspect to consider is the fitting size and thread type. Proper sizing ensures a tight seal and prevents leaks, which can not only lead to inefficiencies but also pose safety risks. The Society of Automotive Engineers highlights that even a small leak can lead to significant fluid loss in hydraulic systems, underlining the need for precision in fitting selection. Matching thread types—whether NPT, BSP, or others—plays a pivotal role in maintaining structural integrity and performance.

Tips: When selecting hydraulic fittings, always consult with professionals or utilize industry-specific software tools for compatibility checks. Regular maintenance checks of the hydraulic system can also help identify potential issues with fittings before they lead to larger problems. Additionally, it can be beneficial to stay updated with the latest industry standards and technological advancements in fittings to enhance overall system reliability and efficiency.

When selecting hydraulic fittings, the material used is as crucial as the fitting's design. Common materials include steel, stainless steel, brass, and plastics, each with distinct advantages and disadvantages. Steel, for instance, is valued for its strength and durability, making it suitable for high-pressure applications. However, it also comes with a downside: susceptibility to corrosion if not properly coated or maintained. Statistics from the Hydraulic Institute suggest that nearly 30% of hydraulic system failures are linked to improper material selection, underscoring the importance of choosing the right fitting material.

Stainless steel offers a robust alternative, boasting excellent corrosion resistance, ideal for applications involving harsh chemicals or extreme environments. Yet, this protection often comes at a higher cost, impacting budget considerations for many projects. Brass, while less expensive and easy to work with, is generally more appropriate for low-pressure applications due to its lower tensile strength. A study by the Fluid Power Society indicates that while brass accounts for about 15% of hydraulic fittings in use, its performance in high-stress situations may lead to premature failure.

Tip: Always evaluate the operating environment and the type of fluids being used in your application. For hydraulic systems exposed to aggressive chemicals, opt for stainless steel over brass to enhance longevity and reliability. Additionally, consider the temperature and pressure ranges specified in your project to ensure compatibility with the chosen material.

This chart illustrates the durability ratings of various hydraulic fitting materials. Steel is rated the highest due to its strength, followed by stainless steel, aluminum, brass, and plastic, which has the lowest durability rating among the materials listed.

When selecting hydraulic fittings for your projects, understanding common application scenarios is crucial. Hydraulic fittings play a vital role in connecting hoses, tubes, and pipes, ensuring the smooth operation of hydraulic systems in various settings, from industrial machinery to agricultural equipment. For example, swivel fittings are commonly used in applications where flexibility and movement are required, such as in construction machinery or mobile equipment. Their ability to rotate allows for easier alignment and reduces the risk of hose kinking.

Another prevalent application is in static systems, such as hydraulic power units, where straight and elbow fittings are often used. These fittings provide secure connections while minimizing pressure drops and flow disruptions. In fluid transfer systems, quick disconnect fittings offer convenience, allowing for fast and easy changes without the need for tools, which is beneficial in environments where downtime must be minimized.

Tips: When choosing hydraulic fittings, always consider the working pressure and temperature of your system to ensure compatibility. Additionally, pay attention to the material of the fittings, as it should be compatible with the fluids being used to prevent corrosion and leaks. Lastly, ensure that the size of the fittings matches your hoses and pipes precisely to maintain optimal performance.

| Fitting Type | Common Application | Size Range (inches) | Pressure Rating (psi) | Material |

|---|---|---|---|---|

| JIC Fittings | General hydraulic applications | 1/8 to 2 | 3000 | Steel, Stainless Steel |

| NPT Fittings | Water and gas applications | 1/8 to 4 | 1500 | Brass, Steel |

| BSP Fittings | International standards, general use | 1/8 to 3 | 2000 | Steel, Plastic |

| ORFS Fittings | Sealing applications under pressure | 1/4 to 2 | 3000 | Aluminum, Steel |

| Flange Fittings | Heavy-duty applications | 2 to 12 | 5000 | Steel, Cast Iron |

Maintaining hydraulic fittings is essential for ensuring their longevity and optimal performance in any project. Regular inspection should be a fundamental part of maintenance; operators should check for signs of wear, leaks, or corrosion. Proper tightening of fittings according to manufacturer specifications can prevent leaks and improve the overall efficiency of the hydraulic system. Additionally, using compatible fluids is crucial, as certain substances can degrade materials and lead to premature failure.

Another important aspect of maintenance is cleanliness. Contaminants within the hydraulic system can cause significant damage over time. Regularly replacing filters and using clean hoses and connectors will help to minimize the risk of dirt and debris compromising the fittings. Moreover, keeping the working environment tidy can further protect hydraulic components and extend their life, ensuring that projects run smoothly and efficiently. By incorporating these maintenance tips into your routine, you can greatly enhance the performance and reliability of your hydraulic fittings.