Empowering Engineering Excellence: Innovate, Elevate, Deliver.

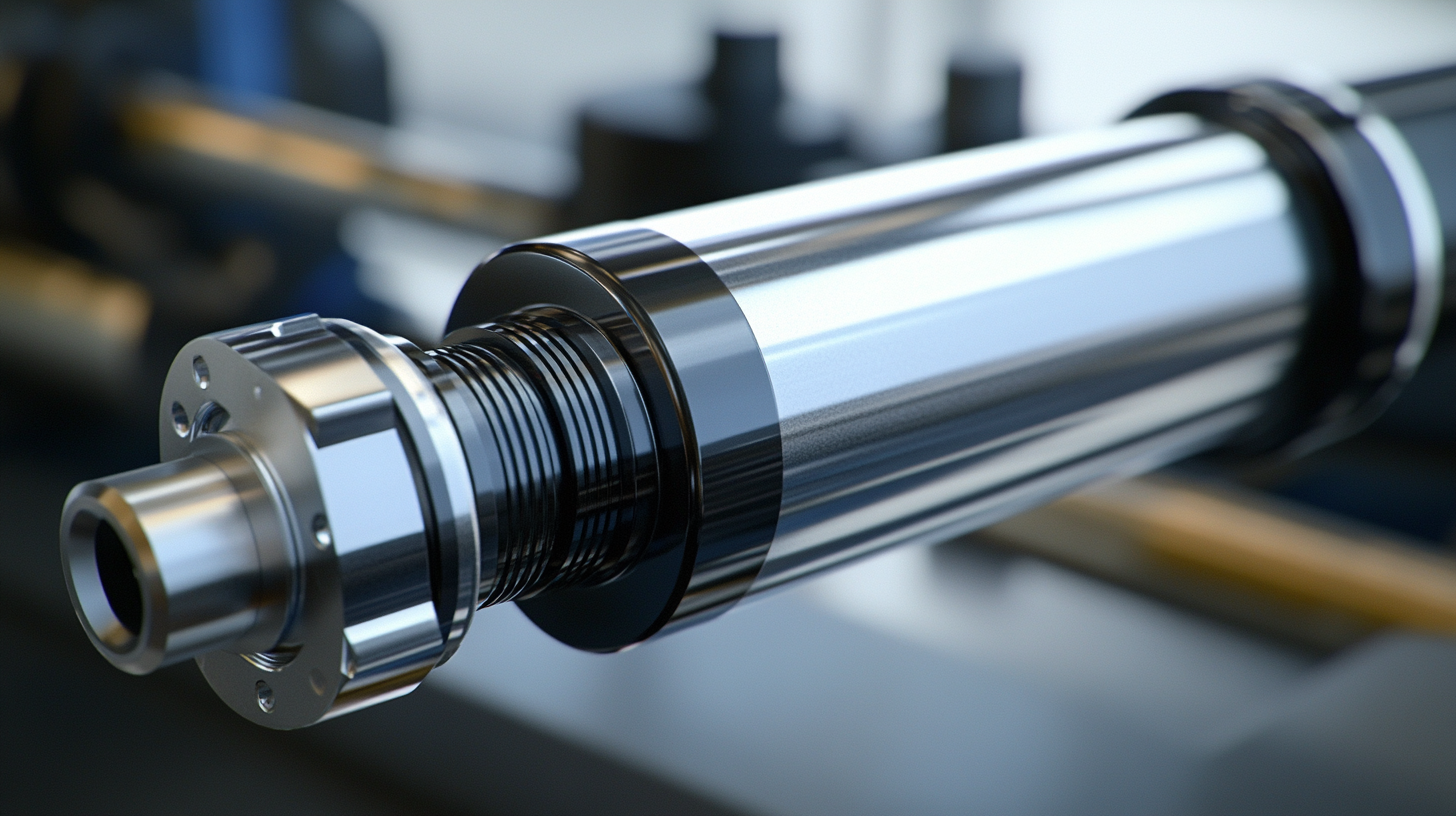

In today's globalized economy, sourcing the right components for machinery and equipment can greatly affect operational efficiency and productivity. Among these essential components are Hydraulic Ram Cylinders, which play a crucial role in a variety of applications, from construction equipment to manufacturing processes. Understanding the intricacies of sourcing these vital components worldwide is imperative for businesses looking to maintain a competitive edge, reduce costs, and ensure reliability in their operations.

This comprehensive guide aims to provide insights into the best practices for sourcing Hydraulic Ram Cylinders globally. We will cover the factors influencing selection, quality assurance measures, and the advantages of working with reputable suppliers. Whether you are a manufacturer, a procurement specialist, or an engineer, this handbook will equip you with the knowledge to navigate the complexities of the global market and secure the hydraulic solutions that meet your specific needs.

Hydraulic ram cylinders are essential components in various industrial applications, offering significant benefits in terms of efficiency and power. There are several types of hydraulic cylinders, each suited to different uses, such as double-acting and tie-rod cylinders. The versatility of hydraulic ram cylinders makes them indispensable in industries ranging from manufacturing to construction, where they perform tasks like lifting, pushing, and pulling. The global hydraulic cylinder market is projected to grow significantly, estimated to reach USD 18.3 billion by 2027, up from USD 14.3 billion in 2021. This growth reflects the increasing demand for advanced hydraulic systems in mobile equipment applications. As manufacturers invest in technology to optimize production, techniques like self-programmed machining cycles are enhancing manufacturing efficiency, leading to quicker turnaround times for hydraulic components. This increase in productivity is crucial as industries seek to minimize downtime and maximize operational effectiveness. Moreover, the shift towards lightweight hydraulics is opening new avenues for innovation. Lighter component designs are not only easier to handle but also more efficient in various applications, enabling improved energy consumption and performance. The development of low-pressure water hydraulics represents another key trend, providing a cost-effective alternative to traditional hydraulic systems. These advancements highlight the continuous evolution of hydraulic technologies and their critical role in supporting industrial growth.

When sourcing hydraulic ram cylinders globally, understanding the materials used in their construction is crucial. The barrel, or pressure-containing envelope, of hydraulic cylinders typically employs various types of ferrous and non-ferrous materials. The choice of tubing not only affects the mechanical properties of the cylinders but also their compatibility with different fluids and operating conditions. For example, high-strength steel is often used for its superior pressure retention capabilities, while corrosion-resistant alloys are essential for applications in harsh environments.

Another key consideration in the sourcing process involves the manufacturing standards of the cylinder components. Quality assurance protocols and compliance with international standards are vital to ensure reliability and safety in operation. When selecting suppliers, assessing their certifications and track records can provide insights into their capability in producing durable and effective hydraulic components. Additionally, evaluating the supply chain logistics from different regions can influence delivery times and costs, making it an essential factor in the decision-making process for sourcing hydraulic ram cylinders on a global scale.

Furthermore, maintaining a good relationship with suppliers can facilitate better communication regarding material specifications and customization options. As industries evolve, the demand for specialized hydraulic solutions increases, prompting suppliers to innovate and adapt. Engaging with suppliers who are responsive to emerging technologies and materials can enhance the overall performance and longevity of hydraulic systems, making sourcing strategies all the more critical.

When sourcing hydraulic ram cylinders on a global scale, identifying reliable suppliers is crucial for ensuring quality and consistency. One of the best practices for finding trustworthy vendors is to conduct thorough research. Start by evaluating suppliers’ backgrounds, including their experience in the industry, reputation, and certifications. Look for reviews or testimonials from previous clients, which can provide insight into their reliability and product quality.

Another important tip is to establish clear communication channels with potential suppliers. Effective communication can prevent misunderstandings and ensure that both parties are aligned in expectations. When discussing specifications, inquire about their manufacturing processes, quality control measures, and after-sales support. This dialogue not only helps clarify your requirements but also fosters a strong relationship built on transparency and trust.

Additionally, consider visits to suppliers’ facilities or third-party audits, if feasible. Seeing their operations firsthand can provide reassurance about their capabilities and commitment to quality standards. In today’s digital age, virtual meetings can also serve as an effective alternative to on-site visits. By leveraging available technology, you can still evaluate their operations while building a rapport with the supplier.

Navigating the complexities of import regulations and compliance for hydraulic ram cylinders requires a thorough understanding of the legal landscape. The Customs Act of 1962 outlines specific provisions regarding the importation of goods into India, and Section 111 indicates that confiscation may occur if goods are brought into the country in violation of these regulations. This underscores the importance for importers to be fully informed about the applicable laws and to ensure that all required documentation is correctly filed to avoid unnecessary penalties.

In the global market, manufacturers face additional challenges, particularly when sourcing from countries facing trade barriers. Recent tensions between the U.S. and Chinese manufacturers have highlighted how geopolitical factors can influence importation routes and tariffs. Companies operating in regions with potential for trade disputes must develop strategies to assess risks associated with tariffs and compliance requirements, particularly when sourcing hydraulic cylinders and other critical components.

Furthermore, staying updated on compliance advisories and regulatory shifts, such as those issued by environmental agencies, is essential for businesses involved in the importation of hydraulic cylinders. These advisories can impact not just financial costs, but also the operational viability of suppliers. Organizations must establish robust compliance frameworks to mitigate risks and foster smoother trade operations in an increasingly complex international business environment.

When it comes to sourcing hydraulic ram cylinders, understanding the cost factors involved is crucial for effective budgeting. Numerous elements contribute to the overall price of hydraulic ram cylinders, making it essential for buyers to conduct thorough research. Material quality, manufacturing processes, and design specifications are primary considerations that directly impact cost. Higher quality materials, such as specialized steel or corrosion-resistant coatings, can significantly raise the price but may offer long-term savings through increased durability.

Another significant factor in the budgeting process is the supplier's location. Importing hydraulic ram cylinders from international suppliers can entail additional expenses such as shipping fees, tariffs, and customs duties. Conversely, sourcing locally might reduce these costs, but the price may vary based on the suppliers available in the area. Engaging with multiple suppliers to compare quotes can also reveal hidden costs associated with warranty services and return policies, which should be factored into the overall budget.

Furthermore, it's vital to account for the scale of the purchase. Bulk orders often come with discounts, but it’s essential to balance the initial outlay with projected demand. Planning for future maintenance and potential replacements should be part of the budgeting strategy as well, since the life cycle of hydraulic ram cylinders can affect long-term expenditures. By carefully evaluating these cost factors and creating a comprehensive budget, buyers can ensure they are making well-informed decisions in their sourcing efforts.