Empowering Engineering Excellence: Innovate, Elevate, Deliver.

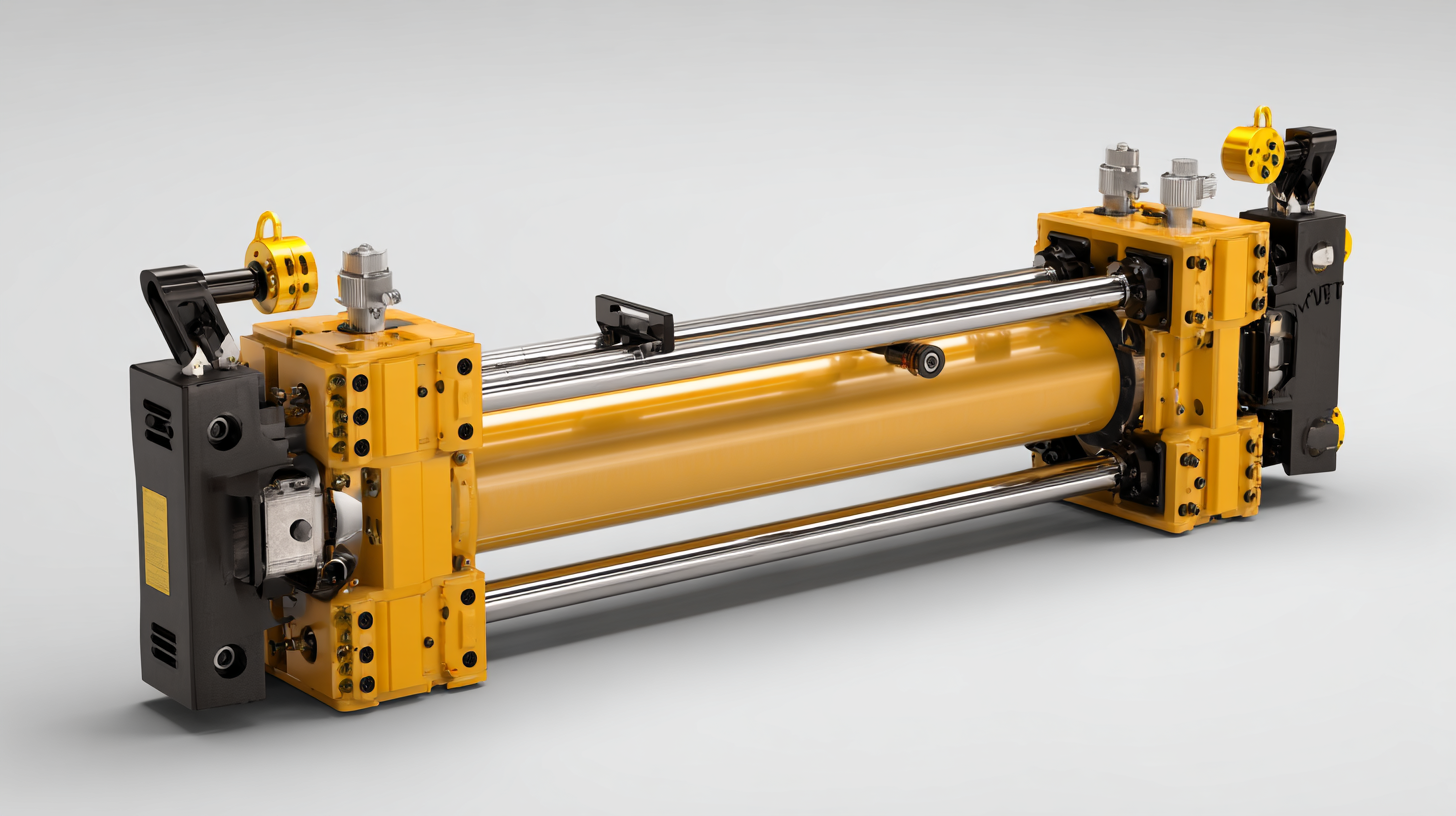

As industries around the globe continue to evolve, the role of hydraulic cylinders becomes increasingly pivotal in driving efficiency and growth. These powerful components, essential in various applications from construction to manufacturing, are witnessing a wave of innovations that promise to enhance their performance and reliability. In the context of "China's Quality Manufacturing, Your Global Partner," it is crucial to explore how cutting-edge technologies and advanced materials are transforming hydraulic cylinders into more effective tools for modern industry. This blog will delve into the latest developments in hydraulic cylinder design and functionality, showcasing how these innovations are not only meeting the demands of today’s industrial landscape but are also paving the way for a sustainable and prosperous future. Join us as we investigate the exciting advancements that are positioning hydraulic cylinders at the forefront of global industrial growth.

The hydraulic cylinder industry is undergoing a transformative phase, marked by innovative technologies that are revolutionizing manufacturing processes. As stated in a recent report by MarketsandMarkets, the global hydraulic cylinders market is projected to reach USD 19.2 billion by 2025, growing at a CAGR of 4.2% from 2020. This growth is largely driven by advancements in smart manufacturing and automation, where hydraulic cylinders play a crucial role in enhancing efficiency and operational reliability.

Among the innovations, the integration of IoT (Internet of Things) technology is particularly noteworthy. Hydraulic cylinders equipped with smart sensors can provide real-time data on performance metrics such as pressure, temperature, and stroke length. According to a study published in the Journal of Manufacturing Processes, the application of IoT in hydraulic systems can lead to a reduction in maintenance costs by up to 30%, as predictive analytics allow for timely interventions before failures occur. Additionally, advancements in materials science are enabling the development of lighter and more durable hydraulic components, further enhancing their effectiveness in various industrial applications, from construction to aerospace. This synergy of technology and materials science is not just enhancing performance but is also paving the way for sustainable industrial practices.

| Dimension | Feature | Innovative Technology | Impact on Industry |

|---|---|---|---|

| Bore Diameter | Increased Efficiency | Advanced Sealing Technologies | Reduces Energy Consumption by 15% |

| Stroke Length | Enhanced Load Capacity | High-Strength Alloys | Increases Lifespan by 20% |

| Operating Pressure | Compact Design | Smart Sensors Integration | Improves Safety Monitoring |

| Weight | Lightweight Structure | 3D Printing Technologies | Reduces Transportation Costs |

| Temperature Range | Thermal Stability | Heat-Resistant Materials | Expands Usability in Harsh Environments |

The role of hydraulic cylinders is increasingly critical in promoting sustainable industrial practices. With the global industrial hydraulic equipment market projected to reach USD 52.6 billion by 2033, reflecting a CAGR of 5.7%, the shift towards energy-efficient solutions is paramount. Recent analyses highlight that the demand for hydraulic cylinders is driven by the need to lower emissions across various industrial sectors. Companies are prioritizing innovations such as speed-controlled hydraulic cylinders, which enhance energy efficiency by minimizing control valve throttling and reducing losses in hydraulic power units.

Tip: When considering hydraulic systems for your operations, focus on equipment that incorporates energy-saving technologies. This not only aids in reducing operational costs but also aligns your business with sustainable practices.

Additionally, the increasing emphasis on eco-friendly solutions is reshaping the hydraulics landscape. Manufacturers are investing in research and development to produce hydraulic components that accommodate energy efficiency and sustainability. As the fluid power industry evolves, the integration of green technologies and services is expected to gain traction, facilitating a more sustainable industrial framework.

Tip: Stay informed about the latest advancements in hydraulic technology by subscribing to industry reports and publications. This insight can help you make informed decisions that enhance your operations while contributing to environmental sustainability.

China has established itself as a powerhouse in the global hydraulic cylinder market, driven by rapid industrialization and technological advancements. With a vast manufacturing base, the country produces innovative hydraulic cylinders that cater to various sectors, including automotive, construction, and agriculture. This competitive edge is largely due to substantial investment in research and development, fostering new materials and designs that enhance performance and durability.

**Tips for Choosing Hydraulic Cylinders:**

When selecting hydraulic cylinders for your application, consider the operating environment and load requirements. Ensure you choose cylinders made from high-quality materials that can withstand harsh conditions while maintaining efficiency. Additionally, evaluating the manufacturer's reputation and after-sales support is critical, as this can significantly impact the longevity and performance of your investment.

Furthermore, China's ability to offer cost-effective solutions without compromising quality gives it an advantage in the ever-growing global market. As industries worldwide increasingly adopt automation and advanced machinery, the demand for reliable hydraulic cylinders will continue to rise, solidifying China's leading position for years to come.

This chart illustrates the projected growth of the global hydraulic cylinder market from 2019 to 2024, showcasing significant increases driven by innovations and industrial demands.

Quality assurance is a critical aspect of the hydraulic cylinder manufacturing process, ensuring that every component meets the highest standards of performance and reliability. Advanced quality assurance practices involve rigorous testing protocols that evaluate the durability, strength, and functionality of each hydraulic cylinder. By implementing non-destructive testing methods, manufacturers can identify potential flaws without compromising the cylinder's integrity, allowing for faulty products to be discarded before they reach the market.

In addition to testing, adherence to international quality standards plays a significant role in ensuring superior performance. Certifications such as ISO 9001 guide manufacturers in establishing effective quality management systems. These systems enhance process efficiency and promote continuous improvement, leading to hydraulic cylinders that not only meet but exceed industry expectations. Furthermore, incorporating feedback from end-users into the design and manufacturing process allows for innovative solutions that address specific performance challenges, ultimately driving global industrial growth.

The industrial landscape is undergoing a transformative shift with the rise of smart hydraulic cylinders and automation technologies. According to market projections, the global hydraulic cylinder market size is expected to reach $6.352 billion by 2025 and soar to approximately $13.1403 billion by 2033. This remarkable growth underscores the increasing integration of sophisticated technologies that not only enhance the efficiency of hydraulic systems but also significantly reduce operational costs for various industries.

One of the key trends driving this change is the adoption of smart hydraulic cylinders equipped with sensors and IoT capabilities. These advanced systems allow for real-time monitoring and data analytics, enabling businesses to optimize performance and predict maintenance needs. Therefore, manufacturers can expect improved durability and uptime of hydraulic equipment. Furthermore, the automation of hydraulic systems facilitates seamless interactions between machines and software, creating a more agile and responsive manufacturing process. This innovation is not just about enhancing individual components but signifies a shift towards smarter, connected industrial operations that are geared towards sustainable growth.