Empowering Engineering Excellence: Innovate, Elevate, Deliver.

When it comes to equipping your workshop with the right tools, selecting the perfect Small Hydraulic Jack can make a significant difference in your efficiency and safety. Whether you're a seasoned mechanic or a hobbyist, having the right hydraulic jack is essential for lifting vehicles, heavy equipment, and performing maintenance tasks with ease. However, with so many options available on the market, finding the one that best suits your needs can be overwhelming. This blog aims to guide you through five essential tips for choosing the right small hydraulic jack, ensuring that you make an informed decision. By understanding the various features, capacities, and specifications, you will be better equipped to select a hydraulic jack that not only meets your workshop requirements but also enhances your overall productivity and safety.

When selecting the right hydraulic jack for your workshop, understanding the necessary size and specifications is paramount. The optimal jack should easily lift your equipment's weight and suit your workspace's specific needs. According to a 2022 industry report by the Hydraulic Institute, nearly 30% of accidents arise from using inappropriate lifting equipment, underscoring the importance of choosing the correct size hydraulic jack.

When assessing the weight capacity needed, consider the maximum weight of the vehicles and machinery you’ll be lifting regularly. A hydraulic jack’s capacity usually ranges from 1 ton to over 100 tons; however, a common recommendation is to select a jack with a lifting capacity of at least 1.5 times your heaviest load to ensure safety and reliability.

It’s also crucial to evaluate the lifting range. Ensure the jack can reach the necessary height for the tasks you undertake. For standard vehicles, a lift range of about 3 to 20 inches is sufficient, while heavier machinery may require larger ranges. Keep in mind that stability is equally important—select a jack with a wide base for enhanced support, especially for larger weights. Ultimately, proper size selection not only promotes efficiency but also enhances safety in your workshop.

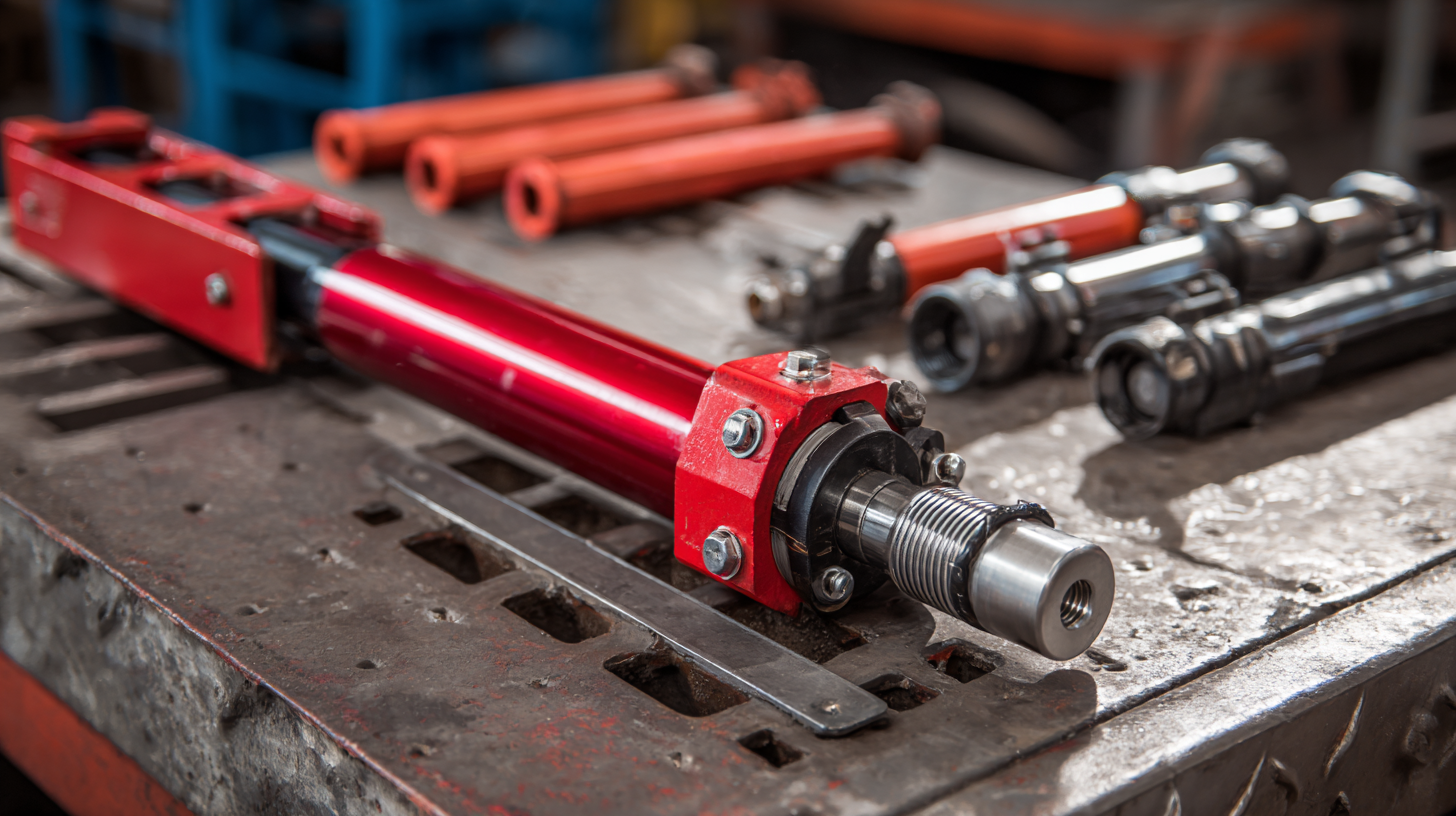

When selecting the right small hydraulic jack for your workshop, understanding the different types available and their specific applications is crucial. Hydraulic jacks generally fall into categories such as bottle jacks, floor jacks, and transmission jacks, each designed for unique tasks. For instance, bottle jacks are compact and highly portable, making them ideal for lifting heavy loads in tight spaces. According to the American Journal of Mechanics, over 50% of workshops prefer using bottle jacks for versatility in various maintenance tasks.

When selecting the right small hydraulic jack for your workshop, understanding the different types available and their specific applications is crucial. Hydraulic jacks generally fall into categories such as bottle jacks, floor jacks, and transmission jacks, each designed for unique tasks. For instance, bottle jacks are compact and highly portable, making them ideal for lifting heavy loads in tight spaces. According to the American Journal of Mechanics, over 50% of workshops prefer using bottle jacks for versatility in various maintenance tasks.

Tip 1: Consider the weight capacity you require. Most small hydraulic jacks range from 2 tons to 12 tons. Choosing a jack with a weight capacity exceeding your typical lifting needs ensures safety and efficiency.

Transmission jacks are specifically engineered for lifting and supporting vehicle transmissions during repairs. They often include adjustable cradles and support arms, which are essential for safely handling heavy components. Recent industry reports indicate that about 30% of automotive workshops utilize dedicated transmission jacks for improved safety and ease of use.

Tip 2: Pay attention to the jack's lifting height and range. Jacks with adjustable heights provide greater flexibility, allowing you to work on various vehicles and equipment without hassle. This feature is especially beneficial in workshops where different types of projects are common.

When selecting a small hydraulic jack for your workshop, evaluating weight capacity is paramount. Understanding how much lift you actually need will ensure you invest in the right tool for the job. Start by considering the heaviest item you plan to lift. It's crucial to choose a jack that can handle this weight comfortably, offering a margin for safety to account for any unexpected factors during operation.

Additionally, think about the types of projects you regularly undertake in your workshop. If you often find yourself working on vehicles, for example, a jack with a higher weight capacity might be necessary. On the other hand, lighter equipment may only require a jack with a moderate weight limit. Always refer to manufacturer specifications and guidelines to make an informed decision, and don’t forget to factor in the height range of the jack to ensure it can accommodate your needs effectively. Remember, choosing the right hydraulic jack can significantly enhance your workshop’s efficiency and safety.

| Weight Capacity (tons) | Lift Height (inches) | Type of Jack | Best Use Case | Weight (lbs) |

|---|---|---|---|---|

| 2 | 12 | Bottle Jack | Car Maintenance | 10 |

| 3 | 10 | Floor Jack | Auto Repair | 25 |

| 5 | 8 | Transmission Jack | Heavy Repairs | 40 |

| 2.5 | 14 | Hydraulic Floor Jack | Racing Car Maintenance | 30 |

| 1.5 | 16 | Pneumatic Jack | Light Vehicles | 15 |

When selecting a small hydraulic jack for your workshop, it is crucial to prioritize safety features to protect both the operator and the equipment being lifted. One of the key safety attributes to consider is the overload protection mechanism. According to the Hydraulic Institute, nearly 25% of all hydraulic-related accidents occur due to equipment being overloaded beyond its rated capacity. A quality small hydraulic jack should have an integrated overload prevention system that automatically stops lifting once the weight exceeds its limit, ensuring safe operation.

Another vital safety feature is the presence of a locking mechanism. A study by the Occupational Safety and Health Administration (OSHA) indicated that improperly secured loads can lead to hazardous situations, including injuries and property damage. A hydraulic jack equipped with a reliable locking system will prevent accidental release or collapse of the load, providing peace of mind when working in your workshop. Additionally, it's advisable to look for jacks that feature a durable construction, as materials like high-grade steel can significantly enhance the longevity and safety of the equipment, further supporting the user's safety during lifting tasks.

When it comes to ensuring the longevity and optimal performance of your workshop hydraulic jack, regular maintenance is key. First and foremost, always keep the hydraulic jack clean. After each use, wipe down the exterior to remove any dirt, oil, or grime. This simple step prevents contamination that can affect the internal components over time.

Moreover, check for any signs of wear or damage, such as leaks or cracks in the body, and address these issues promptly to avoid further deterioration.

Another crucial aspect of maintenance is fluid management. Periodically check the hydraulic fluid levels; low fluid can lead to inefficient operation or even failure of the jack. If you notice any discoloration or contamination in the fluid, it's essential to replace it to maintain optimal functionality.

Additionally, inspect the seals and gaskets for wear, as these components can significantly impact the performance and safety of the hydraulic system. By following these maintenance tips, you can extend the lifespan of your hydraulic jack, ensuring it serves you well for years to come.