Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In today's industrial landscape, the importance of reliable and high-quality hand pumps cannot be overstated. As businesses seek to optimize their operations, the demand for efficient fluid transfer solutions continues to grow. Hand pumps play a crucial role in various applications, from agricultural settings to emergency preparedness. Therefore, navigating the world of hand pump suppliers has become essential for companies aiming to enhance their operational efficiency while ensuring they invest in products that will stand the test of time.

When selecting a hand pump supplier, it is vital to assess not only the quality of the pumps but also the reliability of the supplier itself. With a plethora of options available in the market, understanding the key factors that contribute to a supplier's credibility is paramount. This blog will explore the essential criteria for evaluating hand pump suppliers, ensuring that readers are equipped with the knowledge to make informed decisions that align with their specific needs. By the end of this guide, businesses will have a clearer path to selecting hand pumps that meet their demands for quality and reliability.

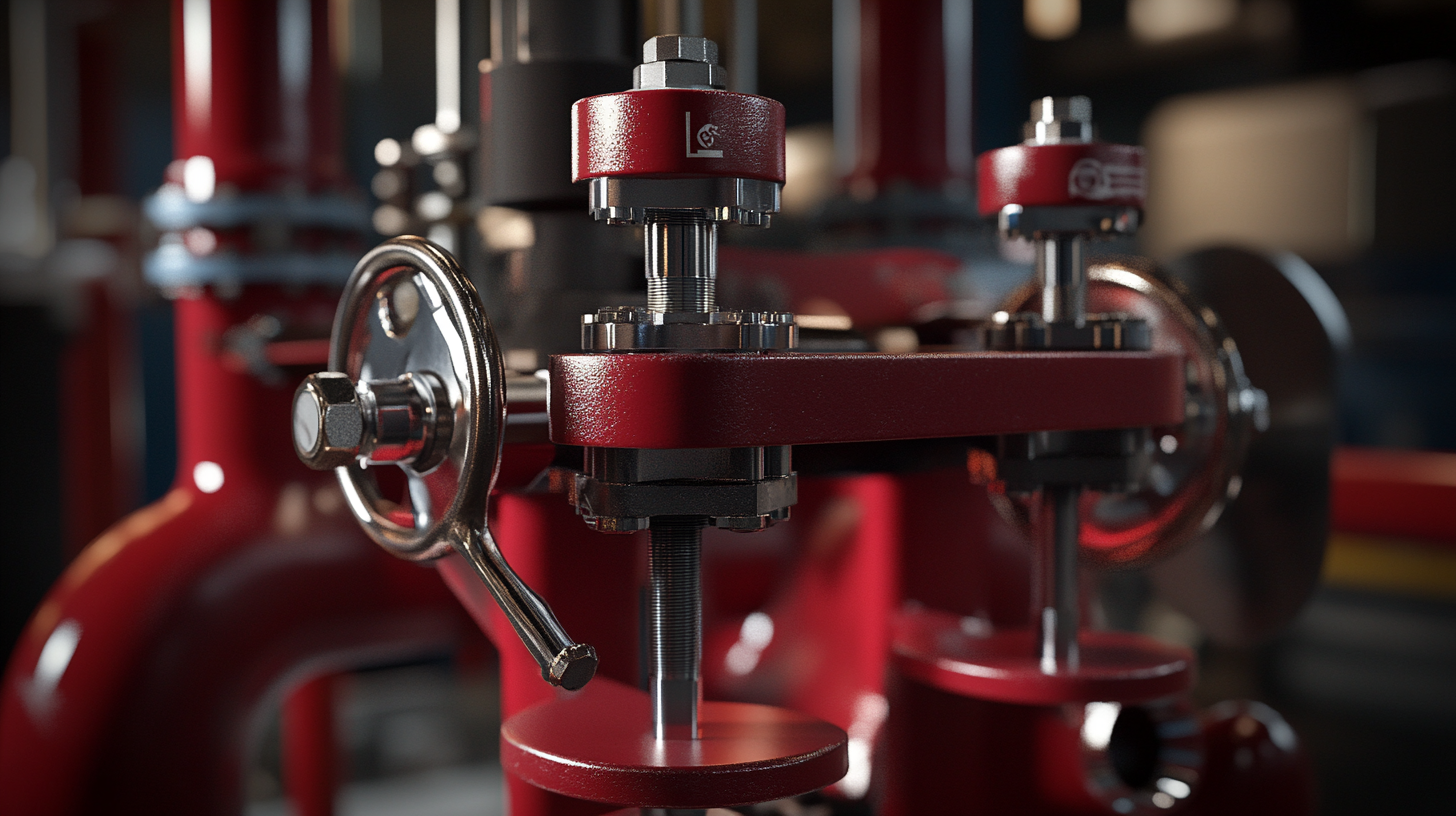

When exploring the realm of hand pump suppliers, identifying the key characteristics of high-quality hand pumps is essential for ensuring optimal performance and reliability. One of the most crucial attributes to consider is the materials used in pump construction. High-quality hand pumps are typically crafted from durable, corrosion-resistant materials such as stainless steel or high-grade plastics, which not only enhance their longevity but also improve efficiency. Suppliers that prioritize these materials demonstrate a commitment to quality that is indicative of their overall product standards. Another critical factor to assess is the design and engineering of the pump. A well-engineered hand pump should feature an ergonomic design that not only facilitates ease of operation but also minimizes user fatigue. Important considerations include the pump's stroke length, handle grip, and overall size, which should all be optimized for both efficiency and comfort. Engaging with suppliers who provide detailed specifications and informative resources can help buyers make informed decisions about which products will best meet their needs. Lastly, reliability often hinges on the supplier's reputation and customer service. Suppliers with a proven track record of excellence in customer support can greatly enhance the purchasing experience, offering guidance on installation, maintenance, and troubleshooting. Positive reviews and testimonials from other customers serve as valuable indicators of a supplier's dependability and the quality of their hand pumps. By focusing on these key characteristics, buyers can confidently navigate the marketplace and select suppliers that deliver superior hand pumps for their specific applications.

When selecting a hand pump supplier, assessing their reputation and reliability is crucial for ensuring product quality and operational efficiency. According to a recent report by the Pump Industry Analysts, over 30% of hand pump failures can be traced back to sourcing from low-quality suppliers. This statistic underlines the importance of conducting thorough research before making a purchasing decision.

One effective way to gauge a supplier's reputation is by looking into customer reviews and industry certifications. For instance, suppliers adhering to ISO 9001 standards generally demonstrate superior manufacturing processes and product consistency. Additionally, reviewing case studies and testimonials can provide insights into the supplier's commitment to customer service and their ability to handle challenges in the field.

Another important factor is the supplier's history in the industry. Data from the American Pump Manufacturers Association indicates that suppliers with more than a decade of experience tend to have a higher reliability rate, often achieving 20% fewer warranty claims compared to newer entrants. Partnering with established suppliers can not only enhance the reliability of the equipment but also ensure ongoing support and access to improved technologies.

Overall, investing the time and effort into evaluating potential hand pump suppliers will pay dividends in securing high-quality, reliable products that minimize downtime and maintenance costs in the long run.

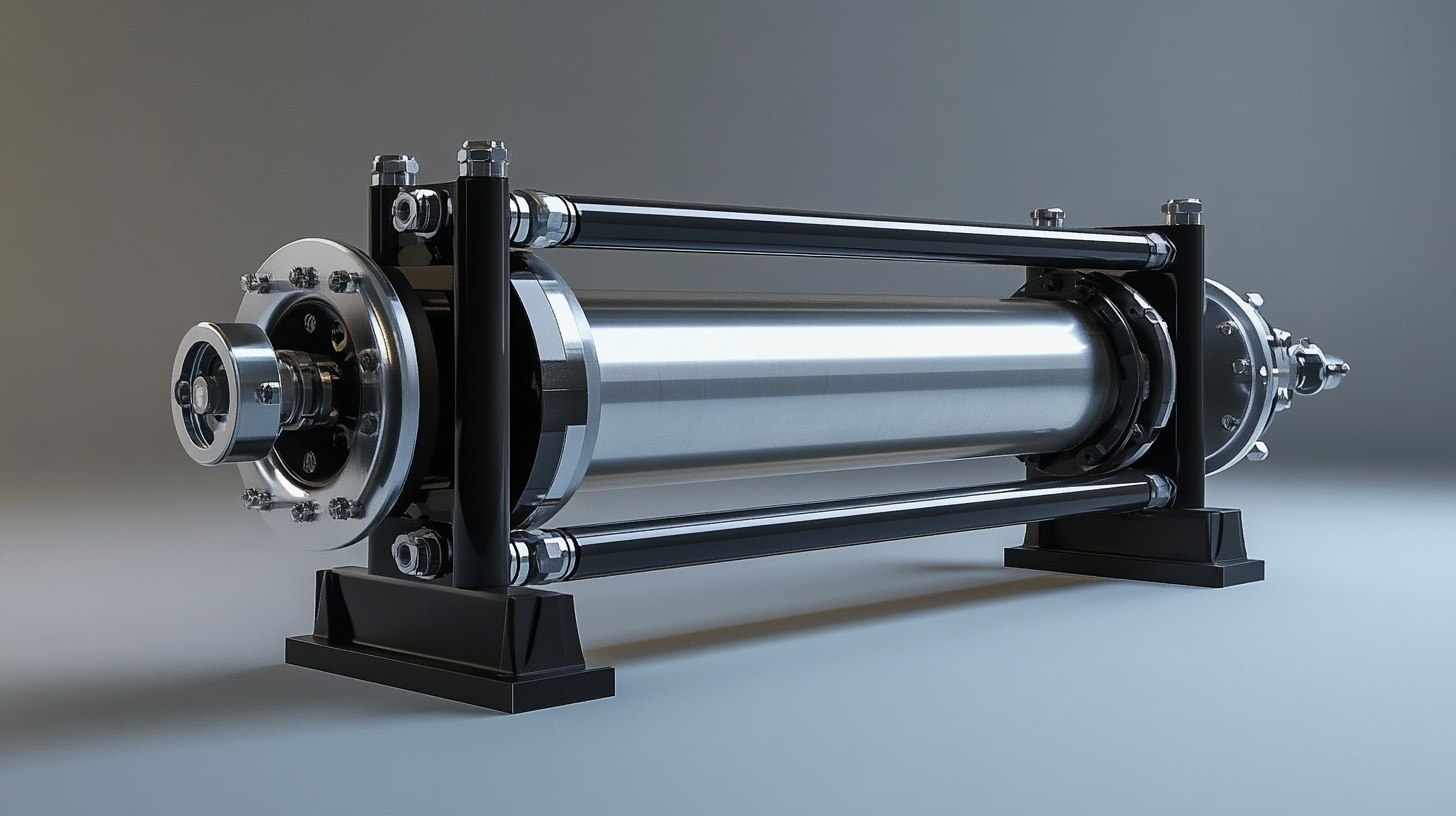

When navigating the world of hand pumps, it is crucial to understand the variety of types available and their specific applications. Hand pumps are essential tools in numerous industries, from agriculture to medical fields. They can range from simple manual devices used for transferring liquids to more complex models designed for specialized functions, such as breast pumps for lactating mothers. Understanding these different hand pump types can significantly enhance their effectiveness in targeted tasks.

The global market for breast pumps, for instance, is projected to exceed $645 million by 2033, with a compound annual growth rate (CAGR) of 8.43% from 2023 to 2033. This surge indicates the increasing demand not only for efficient products but also for quality and reliability in hand pumps designed for personal health applications. Various designs, including manual and electric models, cater to the diverse needs of consumers, emphasizing the importance of selecting the right type based on specific use cases.

Moreover, in industrial settings, hand pumps are utilized for various applications such as fuel transfer, chemical handling, and more. Each application demands a unique design and functionality, reinforcing the necessity for buyers to research and choose suppliers who prioritize product quality and reliability. By exploring different types of hand pumps and understanding their uses, customers can make informed decisions that align with their needs while contributing to their operational efficiency.

When considering the purchase of hand pumps, one of the most critical aspects to evaluate is the balance between cost and quality. According to a recent report by the Market Research Future, the hand pumps market is projected to grow at a CAGR of approximately 5.6% from 2022 to 2027. As demand increases, buyers are often tempted by lower-priced options, but this can lead to compromised reliability and longevity, which ultimately affect operational costs.

Quality hand pumps, while they may come with a higher initial price tag, can offer significant savings in the long run. The American Society for Quality has documented that investing in high-quality equipment can reduce maintenance costs by up to 30%. Quality pumps tend to have materials that withstand wear and tear better, which minimizes downtime and replacement frequency. In contrast, cheaper alternatives may fail more often, resulting in unexpected expenses that can far exceed initial savings.

Moreover, customers need to consider the total cost of ownership. A study published by the National Association of Manufacturers found that businesses often underestimate maintenance and repair costs, which can account for 50-70% of the total expenses associated with equipment over its lifespan. By prioritizing reliable, well-constructed hand pumps, buyers can ensure efficiency and lower the overall financial burden. Hence, while the allure of low-cost options may be strong, the long-term benefits of quality and reliability should guide purchasing decisions in the hand pump market.

In today’s ever-evolving global landscape, establishing long-term relationships with hand pump suppliers is more crucial than ever. With geopolitical tensions and rising trade protectionism, including recent tariffs imposed by the U.S. on various countries, supply chain stability is at a premium. Businesses must emphasize the importance of developing reliable partnerships to better navigate these challenges. A report by the New York Federal Reserve indicates that while global supply chains are recovering, uncertainties remain, making strategic supplier relationships critical for future success.

To forge effective relationships, companies should prioritize communication and transparency. Regular meetings and updates with suppliers can ensure that both parties stay aligned on expectations and standards. Studies show that companies with proactive communication strategies experience a 25% increase in supplier performance metrics. Additionally, focusing on mutual growth through collaborative planning can further solidify these partnerships. Engaging in joint ventures or shared technology initiatives can enhance innovation and product quality, benefiting both suppliers and buyers.

Furthermore, conducting thorough supplier evaluations based on quality, reliability, and responsiveness is essential. Research indicates that organizations that actively assess their suppliers’ capabilities have a higher likelihood of achieving a 30% reduction in operational costs over time. By fostering strategic and transparent relationships, businesses can build a robust supply chain that withstands geopolitical fluctuations and ensures long-term success.