Empowering Engineering Excellence: Innovate, Elevate, Deliver.

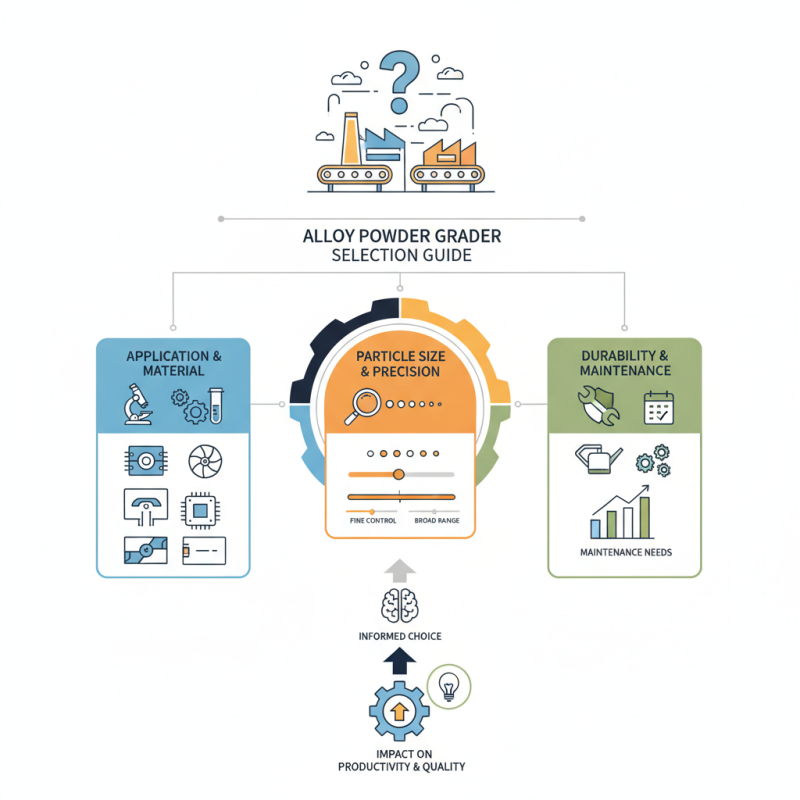

Choosing the right Alloy Powder Grader is essential for various industrial applications. Your selection can significantly impact productivity and quality. With multiple options available, making an informed choice can be challenging.

Different projects require different specifications. An ideal Alloy Powder Grader should match your specific needs. Think about the application, particle size, and material type. These factors will influence your choice. Not every grader performs well in all situations. Some may excel in certain conditions but fail in others.

Consider the level of precision you need. Some grades provide fine control, while others offer broader ranges. Pay attention to the durability and maintenance needs of each option. Reflect on your long-term use and what might limit efficiency. This process may reveal flaws in your initial assumptions, encouraging deeper evaluation.

When choosing an alloy powder grader, understanding the different types available is crucial. Alloy powder graders can be classified broadly into two main categories: mechanical graders and electronic graders. Mechanical graders often rely on physical forces to separate powders. They can be cost-effective and easy to maintain. However, they may not achieve the desired precision in grading. Electronic graders, on the other hand, use advanced technology to sort powders based on size and density. A recent industry report noted that electronic graders can improve accuracy by up to 20% compared to their mechanical counterparts.

In addition, the material composition of the alloys affects the grading process. Different alloys, such as titanium or aluminum, require specific grading techniques to ensure uniformity. For instance, titanium powders tend to clump, making them trickier to grade accurately. Some users may find that their existing graders cannot handle these materials efficiently. A study by the International Powder Metallurgy Association highlighted that nearly 30% of companies experienced issues with powder consistency due to improper grading methods.

Thus, selecting the right alloy powder grader means weighing these types carefully. Mechanical graders are more hands-on, while electronic options provide greater automation. Each type has pros and cons, and often a mixed approach may be necessary. Companies should continuously reassess their grader capabilities to adapt to changing material needs.

Choosing the right alloy powder grader requires careful consideration of specific features. One must evaluate the system's accuracy and precision. These metrics determine how well the grader can produce reliable results. An accurate grader minimizes errors. Precision in measurements ensures consistent quality in the alloy powders.

Another essential aspect to examine is the grading capacity. Different applications require varying throughput levels. Whether for small labs or large production lines, the right capacity makes a significant difference. It's crucial to find a grader that matches your daily needs.

Don't overlook the ease of use. A user-friendly interface is important for efficient operation. Complicated machinery can lead to mistakes. Furthermore, think about maintenance. High-maintenance equipment can become a burden. Reflect on whether the benefits outweigh the difficulties. Choosing wisely helps avoid future complications.

When selecting an alloy powder grader, understanding your specific needs is crucial. Start by identifying the type of alloys you frequently work with. This will guide your choice in size and functionality. Consider the volume of grading required. Are you processing small batches or large quantities? This factor greatly affects the grader's capacity and efficiency.

Tips: Always evaluate the grading accuracy. Some machines may perform well but miss fine particles. Test samples if possible. Focus on user-friendly features, especially if multiple operators will use it. Complicated controls may lead to mistakes.

Think about the maintenance needs as well. A grader that requires frequent upkeep can slow down your operations. Reflect on whether you have the resources and time for regular maintenance. Lastly, analyze the cost versus effectiveness. A cheaper option might save money upfront, but could lead to longer-term issues. It's worth weighing both short-term and long-term benefits before making your choice.

| Criteria | Description | Importance Level |

|---|---|---|

| Particle Size Range | The range of particle sizes that the grader can effectively analyze. | High |

| Material Compatibility | Types of alloy powders that can be graded without damage. | Medium |

| Grading Speed | Time taken to complete a grading cycle. | High |

| Ease of Use | How user-friendly the grading system is for operators. | Medium |

| Data Output Accuracy | Precision of the grading results provided by the equipment. | High |

| Maintenance Requirements | Frequency and complexity of maintenance needed for optimal performance. | Low |

| Cost | Initial investment required for acquiring the grading equipment. | High |

When comparing performance metrics of alloy powder graders, it’s essential to evaluate factors such as particle size distribution, flowability, and morphology. A study conducted by the Materials Research Society revealed that inconsistency in particle size can lead to variances in feeding accuracy. This irregularity can affect the overall efficiency of powder metallurgy processes.

Another critical aspect is flowability, which directly impacts the grading process. Research indicates that optimal flowability can reduce blockage in processing equipment. In some cases, the material itself may have stacking issues, resulting in lower throughput. Proper analysis often highlights the specific conditions required for different alloys. For instance, a study found that certain alloy compositions exhibited flowability issues below 15 degrees of angle of repose.

Morphology plays a crucial role in the behavior of alloy powders. Graders must be chosen based on how morphology affects packing density and flow rates. Having a clear understanding of these metrics can highlight the challenges faced during processing. Not every grader will effectively handle every alloy type, reflecting the need for tailored solutions. As industries adopt more advanced technology, performance evaluation should also focus on compatibility with new methodologies.

When selecting an alloy powder grader, balancing cost and quality is crucial. According to recent industry reports, the global alloy powder market is projected to grow by over 15% annually. This growth reflects a rising demand for high-quality grading solutions. However, it also emphasizes the importance of scrutinizing both cost and performance in grading equipment.

Quality comes at a price. Investing in higher-quality graders often leads to better particle size distribution and enhanced material performance. For instance, studies show that a 10% increase in grading accuracy can improve the efficiency of metal additive manufacturing by up to 20%. Yet, many companies opt for cheaper alternatives. This often results in inconsistent powder quality and lower productivity.

Choosing an alloy powder grader requires careful consideration. Sometimes, the cheapest option may not provide the desired results. A mid-range grader might offer a balance of affordability and performance. In some cases, spending more upfront can lead to lower operational costs in the long run. It's essential to reflect on your unique needs and long-term goals.