Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In today’s rapidly evolving global supply chains, operational efficiency is more crucial than ever. As per a recent report by Supply Chain Dive, companies that implement innovative technologies can see productivity boosts of up to 30%. One such technology making a significant impact is the Single Acting Hydraulic Cylinder, renowned for its ability to streamline operations and optimize equipment performance. According to a market analysis from Mordor Intelligence, the demand for hydraulic cylinders in various industries is projected to grow at a CAGR of 5.8% from 2021 to 2026, indicating a robust upward trend in the adoption of hydraulic systems in supply chain processes.

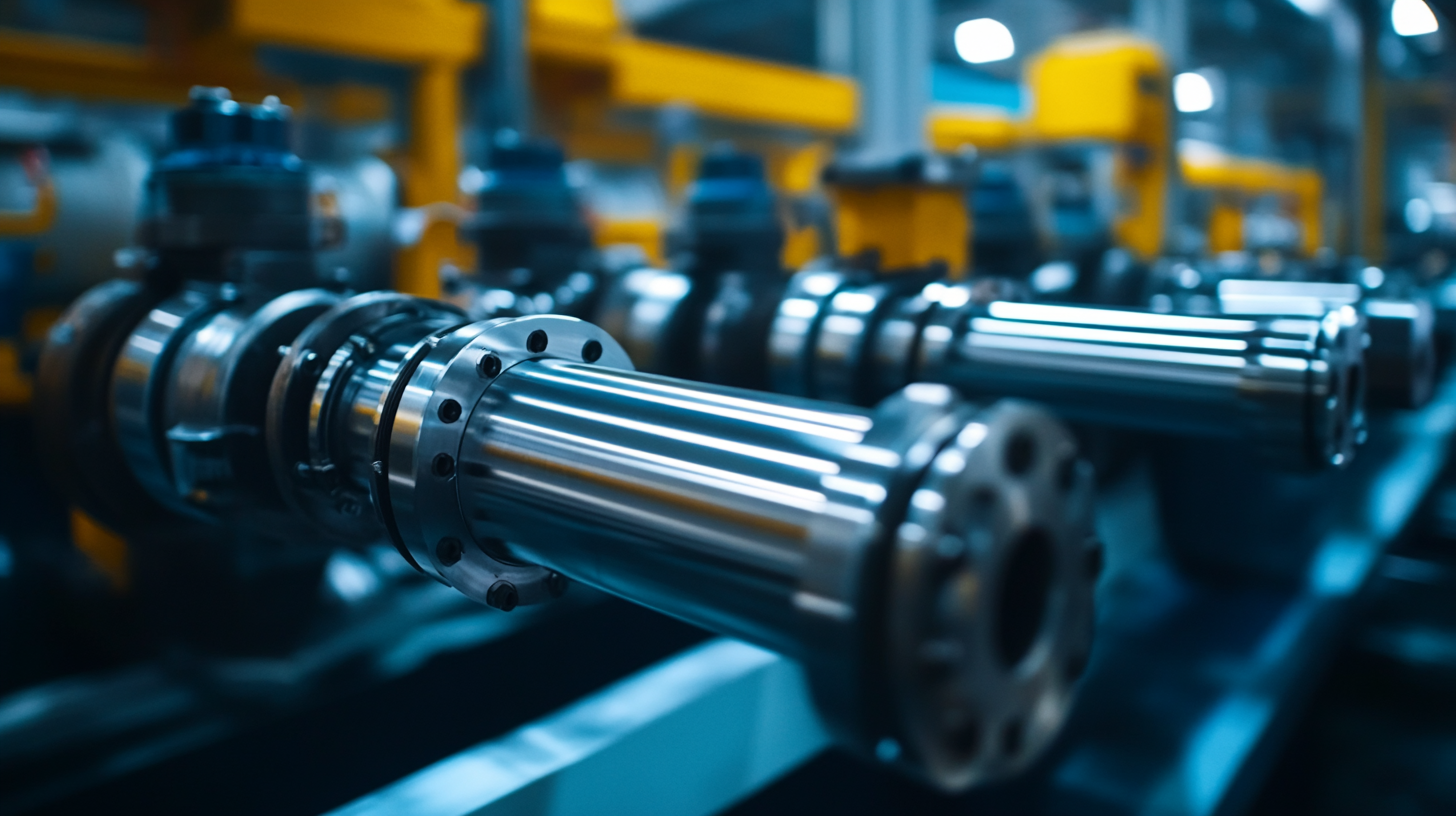

The Single Acting Hydraulic Cylinder distinguishes itself by requiring hydraulic pressure only in one direction, offering a simpler operational mechanism that can reduce both energy consumption and maintenance costs. In an era where cost-efficiency is paramount, organizations are increasingly turning to these cylinders to enhance the reliability and performance of their machinery. A study published by Research and Markets highlights that integrating such hydraulic solutions can lead to reduced downtime and decreased operational overheads—key factors that contribute to the overall agility of supply chains in meeting global demands.

Single acting hydraulic cylinders play a pivotal role in optimizing global logistics operations, particularly as industries embrace a shift towards digitalization and sustainability. In an era where the logistics sector is rapidly evolving, these cylinders provide significant advantages by simplifying machinery design and enhancing operational efficiency. By utilizing the force generated from a single side, they enable streamlined movements in loading and unloading processes, which is crucial in today's fast-paced supply chain environment. As global trade expands and logistics networks become increasingly complex, the need for reliable and efficient machinery becomes paramount. Single acting hydraulic cylinders are designed to meet these demands, offering a robust solution that minimizes downtime and improves productivity. Their application in various logistics operations—from automated sorting systems to dockside cranes—demonstrates how they contribute to faster processing times and reduced operational costs. Moreover, innovations such as electronic fuel delivery systems and automated logistics platforms illustrate a broader trend towards integrating advanced technologies with traditional logistics. These developments not only facilitate smoother operations but also enhance the resilience of supply chains against uncertainties, ultimately paving the way for a more efficient and responsive global logistics environment. As businesses worldwide look to elevate their logistics game, single acting hydraulic cylinders are set to play an integral part in this transformation.

Single acting hydraulic cylinders have emerged as a key component in enhancing supply chain efficiency across various industries. The global hydraulic cylinder market was valued at approximately USD 14.3 billion in 2021 and is projected to grow to USD 18.3 billion by 2027. This growth highlights the increasing demand for reliable and efficient hydraulic solutions that can streamline operations.

One of the most significant advantages of single acting hydraulic cylinders is their superior tipping performance, which allows for smoother and more controlled movements during material handling and transportation. This capability is particularly beneficial in logistics, where timely and efficient loading and unloading are crucial to minimizing downtime. By integrating these cylinders into supply chain operations, companies can achieve heightened reliability and productivity.

Furthermore, single acting hydraulic cylinders are designed for simplicity and ease of use, reducing maintenance requirements and operational costs. Their ability to function effectively with lower hydraulic pressure enhances energy efficiency, making them an environmentally friendly choice. As the supply chain landscape becomes more competitive, investing in such innovative hydraulic solutions is vital for businesses aiming to enhance their operational efficiency and drive growth.

In the realm of global supply chains, the efficiency of machinery can significantly impact productivity. Recent industry statistics reveal that the implementation of single acting hydraulic cylinders can enhance productivity by an impressive 30%. This increase in efficiency is not merely anecdotal; it is backed by rigorous data from various reports. For instance, the International Society of Automation (ISA) reported that industries integrating advanced hydraulic systems effectively reduced cycle times, optimizing operations across multiple sectors.

Single acting hydraulic cylinders, known for their simplicity and reliability, offer several advantages over traditional multi-acting systems. They require less maintenance and are easier to install, which contributes to decreased downtime. According to a study by the Hydraulic Institute, companies that adopted single acting designs saw a 25% reduction in maintenance costs. This not only improves the bottom line but also ensures a more sustainable operational model.

Furthermore, the versatility of single acting hydraulic cylinders makes them ideal for various applications in manufacturing, warehousing, and logistics. A report from the Global Hydraulic Cylinder Market Analysis indicates that businesses utilizing these cylinders have experienced a substantial increase in load handling capabilities, facilitating better inventory management and quicker turnaround times. With such tangible benefits, it’s clear that investing in single acting hydraulic cylinders can lead to a significant competitive advantage in the dynamic landscape of global supply chains.

In the realm of global supply chains, the efficient operation of manufacturing processes is paramount. Recent case studies highlight the successful integration of single acting hydraulic cylinders, which are proving to be a game-changer for many industries. According to a report by the International Federation of Robotics, the manufacturing sector has witnessed a 12% increase in productivity through the use of advanced hydraulic systems over the past two years. This increase can be directly attributed to the streamlined operations enabled by single acting hydraulic cylinders.

One notable example is in the automotive industry, where companies like Ford have implemented single acting hydraulic cylinders in their assembly lines. This integration has led to a significant reduction in cycle times and boosted output by approximately 15%, as noted in a study by the Society of Automotive Engineers. These cylinders are particularly effective in tasks requiring consistent force application in one direction, making them ideal for pressing, lifting, and clamping operations in a manufacturing setup.

Moreover, a recent analysis by Markets and Markets predicts the hydraulic cylinder market will reach USD 12 billion by 2025, driven largely by advancements in single acting cylinder technology. As manufacturers continue to seek ways to enhance efficiency and reduce operational costs, the data indicates a compelling case for the adoption of this technology. Companies that have utilized these cylinders report not only improved efficiency but also a reduction in maintenance costs, as their simpler design often results in lower wear and tear compared to double-acting options.

The evolution of hydraulic cylinder technology continues to shape the future of global supply chains, driving efficiency and optimizing operations. As industries strive for automation and precision, single acting hydraulic cylinders have emerged as a crucial component. Their design not only simplifies mechanisms but also enhances reliability. Innovations such as improved seals and smart sensors improve performance, enabling companies to monitor and adjust systems in real-time, thereby minimizing downtime and maximizing throughput.

Another trend is the integration of IoT (Internet of Things) capabilities into hydraulic systems. With the ability to collect and analyze data, businesses can predict failures before they occur, ensuring seamless operation throughout the supply chain. This proactive approach allows for more effective maintenance schedules and reduces the risk of unexpected disruptions. Furthermore, manufacturers are exploring lightweight materials that maintain strength while reducing energy consumption, ultimately contributing to sustainability initiatives.

Sustainability is becoming paramount in supply chain management. Hydraulic technologies are evolving to accommodate bio-degradable fluids, enhancing environmental friendliness without compromising performance. As companies look for ways to reduce their carbon footprint, adopting these innovative technologies not only meets regulatory demands but also attracts consumers who favor environmentally responsible practices. The future of hydraulic cylinder technology promises to deliver solutions that align with global supply chain efficiency and sustainability goals, ensuring a competitive edge in an increasingly interconnected marketplace.