Empowering Engineering Excellence: Innovate, Elevate, Deliver.

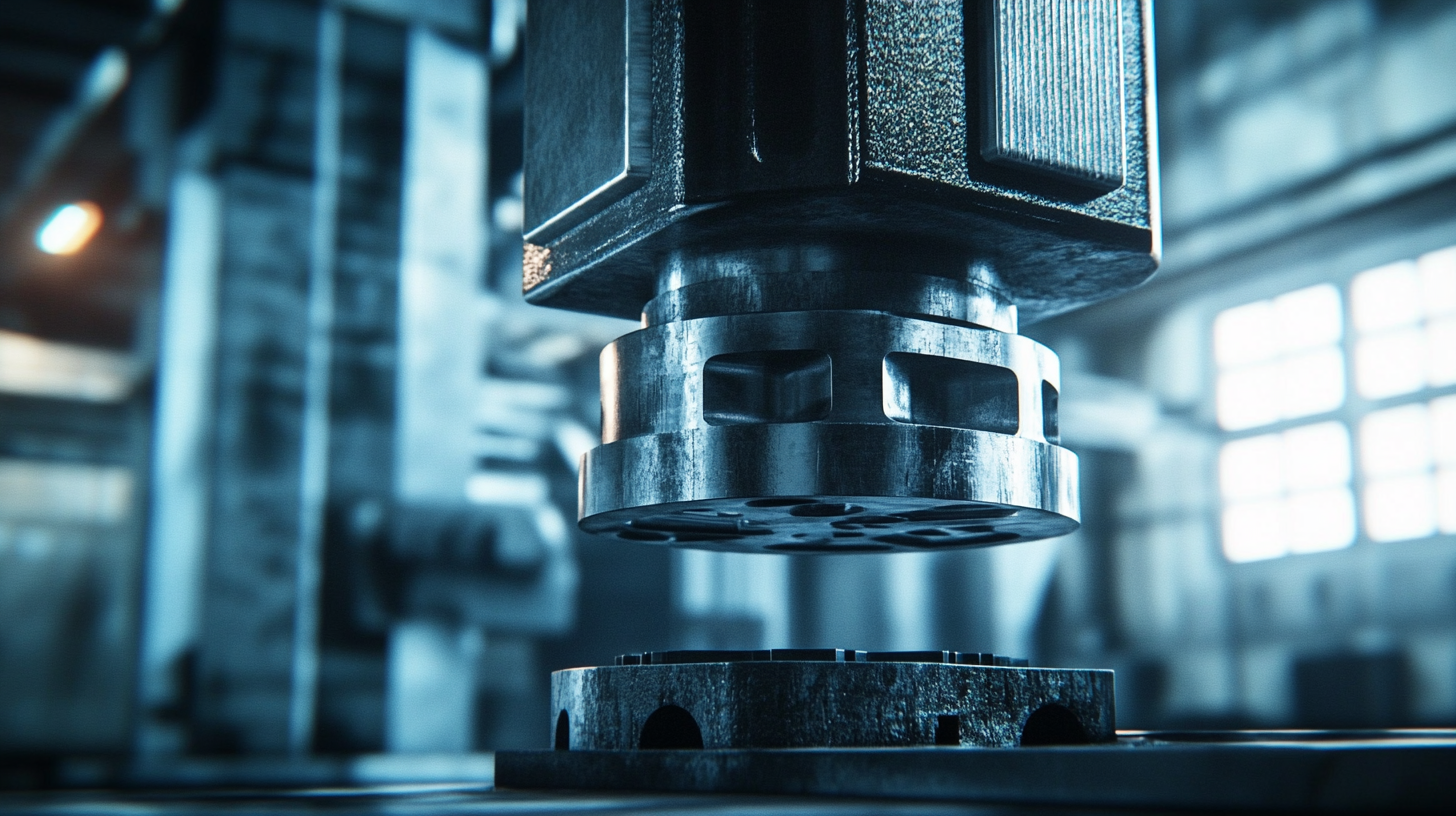

In the ever-evolving landscape of manufacturing, the choice of machinery can significantly influence productivity and product quality, particularly when it comes to hydraulic presses. According to a recent report by MarketsandMarkets, the global hydraulic press market is projected to reach $2.16 billion by 2025, growing at a CAGR of 4.8%. This growth is fueled by the increasing demand for hydraulic press technology across various sectors, including automotive, aerospace, and consumer goods.

Different types of hydraulic presses, such as H-frame, C-frame, and fully automatic presses, each offer unique characteristics and applications tailored to specific manufacturing needs. Understanding these differences is crucial for manufacturers aiming to optimize their operations. This blog will guide you through the various types of hydraulic presses, their distinct features, and how to select the best technology to meet your manufacturing requirements.

In the ever-evolving landscape of manufacturing, the choice of machinery can significantly influence productivity and product quality, particularly when it comes to hydraulic presses. According to a recent report by MarketsandMarkets, the global hydraulic press market is projected to reach $2.16 billion by 2025, growing at a CAGR of 4.8%. This growth is fueled by the increasing demand for hydraulic press technology across various sectors, including automotive, aerospace, and consumer goods.

Different types of hydraulic presses, such as H-frame, C-frame, and fully automatic presses, each offer unique characteristics and applications tailored to specific manufacturing needs. Understanding these differences is crucial for manufacturers aiming to optimize their operations. This blog will guide you through the various types of hydraulic presses, their distinct features, and how to select the best technology to meet your manufacturing requirements.

Hydraulic presses are integral to various manufacturing processes, serving as essential equipment across industries. By understanding the different types of hydraulic presses and their specific applications, manufacturers can make informed decisions about which technology best suits their needs. The major categories include electric, pneumatic, hydraulic, and hydropneumatic presses, each offering unique advantages depending on the operational scenario. For instance, electric presses are known for their energy efficiency and precision, while traditional hydraulic presses excel in heavy-duty applications, making them ideal for metal stamping and forming operations.

The demand for hydraulic technology continues to rise, as evidenced by the growth of the global hydraulic cylinder market, which is projected to expand from USD 14.3 billion in 2021 to USD 18.3 billion by 2027. This growth reflects an increasing integration of advanced pressing technologies into assembly systems. Furthermore, innovative applications, such as isothermal die forging, highlight the versatility of hydraulic presses in achieving high-quality results under controlled conditions. Understanding these dynamics aids manufacturers in optimizing their production capabilities and staying competitive in the evolving industrial landscape.

When selecting hydraulic press technology for manufacturing, several key factors must be considered to ensure that the chosen system aligns with specific operational needs. First and foremost, the capacity of the hydraulic press is critical; it must be sufficient for the materials being processed and the nature of the applications. A thorough assessment of the required tonnage will help in determining the most suitable equipment. Additionally, the speed and efficiency of the hydraulic press can significantly impact productivity, making it essential to evaluate different models and their cycle times.

Another important consideration is the automation level of the hydraulic press. Integrating advanced technology can enhance operational efficiency, allowing for seamless integration into existing production workflows. As technology continues to evolve, the incorporation of smart features can offer significant benefits — from data collection and analysis for performance optimization to features that ensure workplace safety. Just as technology serves as a differentiator in sectors like finance and logistics, the right hydraulic press technology can set a manufacturing operation apart from the competition, driving growth and sustainability in a demanding market.

When selecting the best hydraulic press technology for manufacturing needs, a comparative analysis of top hydraulic press brands reveals significant differences that can influence your decision. Each brand typically offers distinct features, performance capabilities, and pricing structures, making it essential to assess which aligns best with your operational requirements. For instance, brands like Hydraulic Press Company and Baileigh Industrial are renowned for their robust designs and innovative engineering that cater to high-volume production lines, offering models equipped with advanced automation and safety features.

Conversely, companies such as Dake and Shop Press focus on versatility, providing smaller, more adaptable hydraulic presses that excel in various applications, from metal forming to assembly tasks. Their compact models are particularly appealing for workshops with limited space but still needing powerful performance. Additionally, factors like customer service, warranty, and availability of spare parts play a crucial role in brand reliability and overall user satisfaction. Thoroughly evaluating these aspects can help manufacturers identify the ideal hydraulic press that not only meets their current production demands but also supports future growth.

In the dynamic world of manufacturing, the demand for enhanced production efficiency drives innovation in hydraulic press technology. Advanced hydraulic presses are now equipped with features such as programmable logic controllers (PLCs) and real-time monitoring systems. According to a recent report by MarketsandMarkets, the hydraulic press market is anticipated to grow from $4.2 billion in 2021 to $5.8 billion by 2026, with a compound annual growth rate (CAGR) of 6.5%. This growth is largely fueled by the integration of smart technologies that enable manufacturers to optimize processes and reduce downtime.

Moreover, innovations such as servo-driven hydraulic systems offer significant benefits over traditional models. A study by TechNavio indicates that servo-hydraulic presses can improve energy efficiency by up to 30% and increase production speed, thereby meeting the industry's need for sustainable practices. These cutting-edge machines not only provide precise control but also reduce noise levels and maintenance costs, ultimately leading to a more environmentally friendly manufacturing process. As the industry continues to embrace these technological advancements, companies that invest in modern hydraulic press systems will be well-positioned to improve their operational efficiency and competitiveness.

To ensure the longevity of hydraulic presses in your manufacturing operation, regular maintenance is crucial. First, it is important to establish a consistent inspection routine to monitor key components, such as seals, hoses, and fittings. Any signs of wear or leaks should be addressed immediately to prevent costly downtime and further damage to the machine. Additionally, checking fluid levels and quality is vital; maintaining the correct hydraulic fluid can significantly enhance performance and reduce the risk of overheating.

Another essential aspect of hydraulic press maintenance is cleanliness. Keeping the machine and surrounding area free from debris and contaminants can help avoid damage and ensure smooth operation. Operators should be trained to clean the hydraulic press regularly, taking care to remove any build-up that could interfere with its components. Furthermore, it’s advisable to follow the manufacturer’s recommended service schedule for oil changes and part replacements, which can help maximize the efficiency and lifespan of the equipment. Regular maintenance not only prolongs the life of hydraulic presses but also helps in maintaining safety standards in the workplace.

| Technology Type | Max Pressure (psi) | Hydraulic Fluid Type | Ideal Industries | Maintenance Frequency |

|---|---|---|---|---|

| C-Frame Hydraulic Press | 30,000 | AW32 | Automotive, Aerospace | Monthly |

| H-Frame Hydraulic Press | 50,000 | AW46 | Metalworking, Construction | Bi-Annually |

| Four-Post Hydraulic Press | 60,000 | AW68 | Manufacturing, Electronics | Quarterly |

| Bench Hydraulic Press | 20,000 | AW32 | Hobbyist, Small Shops | Annually |

| Custom Hydraulic Press | Varies | Depends on application | Various Industries | As Needed |