Empowering Engineering Excellence: Innovate, Elevate, Deliver.

In the ever-evolving landscape of fluid transfer solutions, the significance of selecting the right Hose And Fittings cannot be overstated. In 2023, the global market for hydraulic hoses and fittings is projected to reach USD 6.94 billion, emphasizing the critical role these components play in diverse industries, from agriculture to manufacturing.

According to a recent report by Grand View Research, the demand for efficient and durable fluid transfer systems continues to surge, driven by rapid industrial expansion and advancements in pressure resistance technology. As businesses strive for higher efficiency and reliability, the choice of Hose And Fittings emerges as a fundamental factor that can significantly impact operational performance.

This blog will explore the seven best solutions available this year, highlighting innovations and best practices that ensure seamless fluid transfer while meeting the rigorous demands of modern applications.

When selecting hoses and fittings for optimal fluid transfer, several key features should be prioritized to ensure efficiency and reliability. First and foremost, compatibility with the type of fluid being transferred is crucial; materials should be resistant to corrosion and degradation to prevent leaks and contamination. Consideration of temperature and pressure ratings is also essential, as stable performance under varying conditions often determines the longevity of the hose and fittings.

Another important feature is flexibility and ease of handling. Hoses that are lightweight and flexible can significantly reduce strain during operation, ensuring that they can be maneuvered into tight spots or around obstacles without kinking or causing flow disruption. Additionally, the design of the fittings should facilitate quick connections and disconnections, streamlining the workflow and minimizing downtime. Opting for fittings with robust sealing mechanisms can further enhance leak prevention and ensure a secure connection during use.

When it comes to efficient fluid transfer, selecting the right materials for hoses and fittings is crucial. Rubber, PVC, and stainless steel each offer unique benefits and drawbacks depending on the application. Rubber hoses provide excellent flexibility and resilience, making them ideal for dynamic environments where movement is frequent. However, they may degrade more quickly when exposed to certain chemicals or extreme temperatures. On the other hand, PVC hoses are lightweight and resist corrosion, making them suitable for transporting a variety of fluids. Their rigidity could be a limitation in scenarios requiring flexibility. Lastly, stainless steel offers high durability and resistance to extreme temperatures and corrosion, making it the best choice for high-pressure applications; however, it can be more expensive and less flexible than rubber or PVC counterparts.

Tips: When selecting materials, consider the specific fluid being transferred and the environmental conditions. Always check compatibility charts for materials to avoid degrading your hoses prematurely. Additionally, think about the long-term costs versus initial investment; sometimes a higher-priced option like stainless steel can save you money in repairs and replacements down the line. Lastly, regular maintenance and inspections can prolong the life of your hoses and fittings, ensuring efficient performance throughout their use.

When it comes to fluid transfer, selecting the right hose diameter and length is crucial for achieving maximum efficiency. According to a 2022 report from the Fluid Transfer Association, an improperly sized hose can reduce flow rates by up to 30%, leading to increased energy consumption and potential system failures. Thus, understanding how these factors interact is essential for optimizing performance.

Tip: Always consider the viscosity of the fluid being transported. For thicker fluids, a larger diameter hose may be necessary to maintain flow efficiency. Additionally, keeping hose length to a minimum can significantly reduce pressure losses, which are often calculated by the Darcy-Weisbach equation. By maintaining a diameter-to-length ratio that aligns with your specific application, you can enhance overall system performance.

Careful evaluation of both hose diameter and length can prevent inefficiencies in fluid transfer systems. A recent study indicated that reducing hose length by just 10% can lead to a 15% improvement in flow rate, illustrating the importance of design in fluid handling environments. Choosing the right configuration not only aids in fluid dynamics but also enhances the lifespan of equipment involved in the transfer process.

In the ever-evolving landscape of fluid transfer solutions, the significance of choosing the right hose and fittings cannot be overstated. The industry has seen substantial growth, with the global hydraulic hose market expected to reach USD 5 billion by 2026, as reported by Research and Markets. This upward trend is driven by advancements in material technology and an increasing demand across sectors such as construction, agriculture, and manufacturing. Leading brands like Gates, Parker Hannifin, and Eaton have distinguished themselves by offering reliable, high-performance products tailored to facilitate efficient fluid transfer while ensuring safety and durability.

A closer inspection of industry leaders reveals that Gates, renowned for its innovative hose designs, offers a comprehensive range of products with advanced reinforcement technologies that enhance their lifespan. Meanwhile, Parker Hannifin, recognized for its engineering prowess, provides tailored solutions for specific applications, ensuring that clients find the perfect fit for their fluid transfer needs. In terms of market share, Parker is projected to hold over 20% of the hydraulic hose market by 2025, illustrating its commanding presence. As companies increasingly prioritize operational efficiency, the strategic selection of hoses and fittings from these top brands becomes crucial for securing optimal fluid transfer performance.

| Hose Type | Material | Diameter (inch) | Pressure Rating (psi) | Temperature Range (°F) | Application |

|---|---|---|---|---|---|

| Garden Hose | Rubber | 0.5 | 150 | 32 - 120 | Watering |

| Hydraulic Hose | Thermoplastic | 1 | 3000 | -40 - 212 | Construction |

| Air Hose | PVC | 0.75 | 200 | 32 - 140 | Pneumatic Tools |

| Chemical Hose | EPDM | 1.5 | 150 | -20 - 180 | Chemical Transfer |

| Food Grade Hose | Silicone | 1 | 200 | -40 - 220 | Food Processing |

| Fuel Hose | Nitrile | 0.75 | 150 | -20 - 180 | Fuel Transfer |

| Industrial Hose | Rubber | 2 | 500 | -20 - 180 | General Purpose |

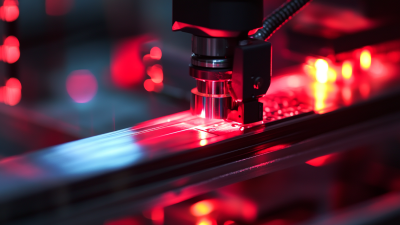

Innovative technologies in

hose and fittings

are revolutionizing fluid transfer processes across various industries in 2023. With increasing demands for

efficiency and safety, manufacturers are investing in advanced materials and designs that enhance performance. For instance, a recent industry report highlights that

thermoplastic elastomer (TPE) hoses are gaining popularity due to their lightweight and flexible nature, which allow for better maneuverability and reduced wear and tear. According to projections, the global hose and fittings market is expected to reach $28 billion by 2026, proving that innovation is becoming essential for competitive advantage.

Innovative technologies in

hose and fittings

are revolutionizing fluid transfer processes across various industries in 2023. With increasing demands for

efficiency and safety, manufacturers are investing in advanced materials and designs that enhance performance. For instance, a recent industry report highlights that

thermoplastic elastomer (TPE) hoses are gaining popularity due to their lightweight and flexible nature, which allow for better maneuverability and reduced wear and tear. According to projections, the global hose and fittings market is expected to reach $28 billion by 2026, proving that innovation is becoming essential for competitive advantage.

When selecting hose and fittings solutions, consider using modular fittings that allow for easy customization and quicker assembly. This not only saves time but also reduces downtime in operations. Additionally, choosing reinforced hoses can provide greater resistance to pressure fluctuations and chemicals, ensuring a longer lifespan and minimizing leaks. Remember to assess the compatibility of your fittings with different fluid types, as improper pairing can lead to inefficiencies and safety hazards.

It’s also crucial to stay updated on the latest innovations in hose technology, such as anti-static properties and temperature resilience. Investing in hoses equipped with these features can improve fluid transfer safety and effectiveness while aligning with environmental regulations. As industries strive for sustainability, embracing these innovative fittings can pave the way for more efficient and eco-friendly operations in fluid transfer.