Empowering Engineering Excellence: Innovate, Elevate, Deliver.

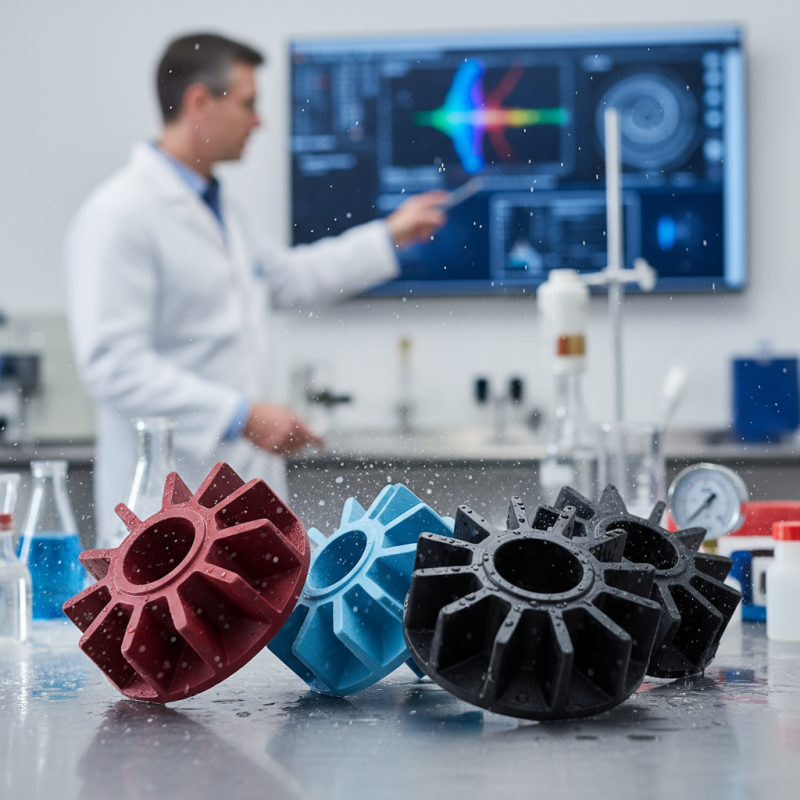

In the world of industrial pumps, the Rubber Pump Impeller stands as a crucial component. Industry expert Dr. John Matthews emphasizes its significance, saying, "A durable impeller can make or break operational efficiency." The demand for high-performance impellers continues to rise, pushing manufacturers to innovate. Choosing the right Rubber Pump Impeller is vital for optimal fluid transfer and long-term reliability.

Performance varies widely among different Rubber Pump Impeller designs. Factors such as material quality and construction can greatly influence efficiency and durability. For instance, some impellers excel in high-temperature environments, while others are best suited for corrosive fluids. Despite advancements, there are still challenges. Improper selection can lead to frequent replacements and operational losses.

Evaluating options can be overwhelming. Trade-offs exist between cost and performance. Each application presents unique demands that require careful consideration. As companies strive for increased efficiency, the need for superior Rubber Pump Impeller choices becomes more critical than ever. Every decision impacts the overall system performance.

Rubber pump impellers play a crucial role in various industries. They are integral to the efficiency of pumps. These components help in moving liquids effectively. The right choice ensures smooth operation. Impellers must withstand various conditions. They deal with different fluid types, temperatures, and pressures.

Applications are diverse. Water treatment plants rely on them for reliable performance. Agriculture uses rubber impellers for irrigation systems. They can also be found in petrochemical processes. Their adaptability makes them valuable. However, not all impellers are created equal. Some may degrade faster than others. Regular inspections are necessary to avoid malfunctions.

Rubber materials provide resilience. They absorb vibrations and reduce noise. This feature enhances user experience. Yet, some users report issues with wear and tear. Over time, impeller efficiency may decline. A thoughtful approach in selecting and maintaining rubber pump impellers can lead to significant improvements.

When selecting rubber pump impellers, several key factors should be considered to optimize performance. The material composition is crucial. Quality rubber impellers typically offer excellent elasticity and resilience under pressure. According to industry reports, using high-grade rubber can extend the life of the impeller by up to 30%. However, not all rubber types perform equally in diverse conditions.

Another significant aspect is the impeller design. Impellers with a more streamlined shape can enhance flow efficiency. Some studies indicate that a properly designed impeller can reduce energy consumption by 15%. Yet, there’s a challenge: finding the right balance between durability and performance can be complex. Sometimes, a more robust design may hinder flow rates.

Temperature and chemical compatibility are vital as well. High temperatures can degrade rubber compounds over time. Reports show that around 20% of impeller failures are related to thermal stress. Regular maintenance and material assessments can help in avoiding these issues. Paying close attention to these factors ensures that the selected impeller will perform reliably in its intended application.

When selecting the best rubber pump impellers for 2026, performance is key. Rubber impellers excel in various applications, providing flexibility and durability. They are often used in water treatment and agricultural industries. Their design allows for efficient fluid movement. It's crucial to focus on the impeller's shape and material. This can greatly affect the pump's overall efficacy.

The market is filled with various models, each offering unique features. Many have open or closed configurations. Open designs may clog less, while closed versions are better for higher efficiency. It's important to assess the operating conditions, such as temperature and pressure. Not all rubber impellers can handle extreme situations. Some may wear quickly under harsh environments. Understanding these factors can help in making an informed choice.

Life isn't perfect, and neither are pump impellers. In some cases, users report diminished performance over time. This can lead to unexpected maintenance needs. Knowing when to replace or upgrade is essential for long-term use. Investing in a quality impeller can save time and costs. Always be ready for change. The right choice today may not hold true tomorrow. Stay updated with the latest technology and user reviews.

When selecting a pump impeller, material choice is crucial. Rubber impellers stand out for their flexibility and endurance. They can handle various liquids. Their resilience makes them suitable for abrasive materials. However, rubber impellers may degrade faster in extreme conditions. That’s something to watch for.

Metal and plastic are popular alternatives. Metal impellers offer high strength but can corrode. They excel in high-pressure situations but lack the flexibility that rubber possesses. Plastic impellers are lightweight and resistant to chemicals but may not handle abrasive materials well.

**Tips:**

Consider the specific application when choosing materials. Look for durability in rubber impellers. Regular maintenance helps extend their lifespan. Checking for wear and tear can prevent failures in the system.

Rubber pump impellers are crucial for optimal performance. To ensure longevity, proper maintenance is essential. One of the most important tasks is regular inspection. Look for signs of wear and tear, such as cracking or deformation. Any irregularities can affect the pump’s efficiency. Replace damaged components promptly to avoid bigger issues later on.

Cleaning is another critical aspect. Debris can accumulate, hindering functionality. Use a soft brush or cloth to remove buildup. Avoid harsh cleaners that might damage the rubber. Sometimes, it helps to soak parts in warm water to loosen grime. Ensure everything is thoroughly dried before reassembly.

Operating under recommended conditions is vital. Extreme temperatures or abrasive liquids can shorten the lifespan. Monitoring performance regularly helps catch problems early. Keep records of maintenance activities to identify patterns. Reflecting on what works or doesn’t often leads to improvements in care routines. Every small step contributes to longer-lasting, efficient impellers.